Ultra-Safe

Explosion-proof / No leakage

Stable

Low Internal Resistance / Proven Stability

Long Life

Ultra-long cycle life

Guaranteed A Grade

Contracted A Grade cell supply

Upgrade to superior deep cycle power with the DCS 12V 100Ah LD (Low Draw) Lithium Battery – the ultimate replacement for outdated AGM, Gel, or lead-acid batteries. Experience lithium-ion technology that delivers exceptional performance, reduced weight, unmatched reliability, and an extended service life – all at a price that outperforms even the most premium lead-acid options.

Say goodbye to bulky, inefficient batteries and make the smart switch today! Contact our Lithium Battery Experts for expert guidance and discover the future of energy storage.

Backed by a 3-year warranty for peace of mind.

Availability: In Stock

Original price was: $799.00.$699.00Current price is: $699.00.

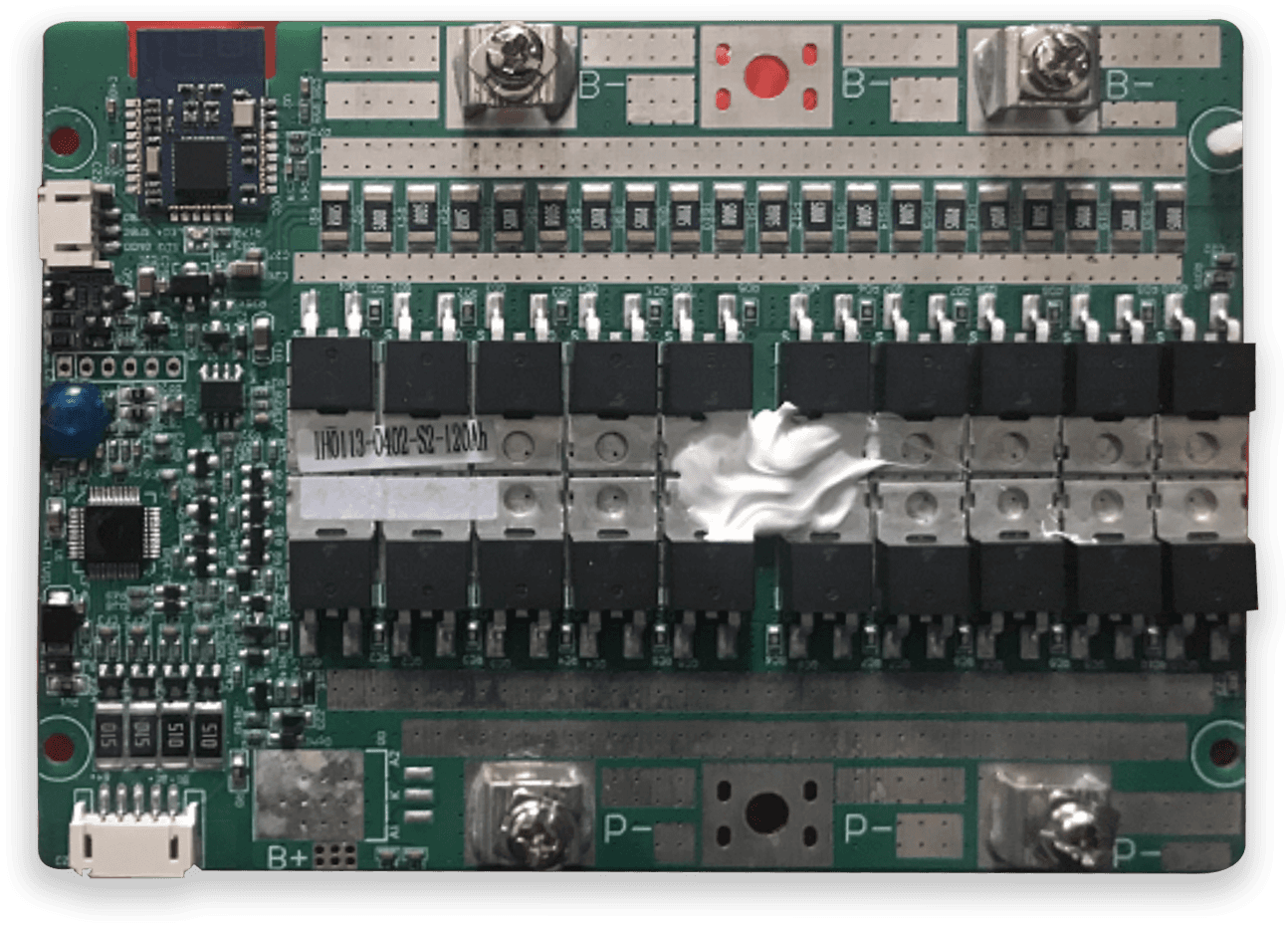

The DCS 12V 100Ah Low Draw Lithium Battery delivers a continuous discharge output of 100A, making it the perfect choice for applications where high currents aren’t required. It supports inverters up to 1200W, making it an efficient and dependable power solution for a variety of 12V appliances and devices. Designed for reliable power delivery with a single integrated circuit design and ultra low standby power consumption, this battery is perfect for running: ✅ 12V appliances such as refrigerators, lighting, water pumps, travel buddy ovens Equipped with a DCS internal Battery Management System (BMS), this battery ensures maximum safety and longevity, protecting against overcharge, over-discharge, and short circuits. The BMS also provides active cell balancing, allowing multiple batteries to be connected in parallel – expand your battery bank with up to ten 100Ah batteries! DCS batteries are renowned for their exceptional safety, durability, and efficiency. This low draw, Bluetooth-free lithium battery offers a superior alternative to lead-acid batteries at a similar price point, while featuring our premium cylindrical cell technology for maximum power and longevity and safety. Click Here for more information

”TEXT” Do you want to replace your underperforming battery with a heavy-duty 12v lithium ion battery for an uninterrupted power supply? Are you looking for an alternative to the old fashioned lead-acid battery? Are you on a hunt for a feature-rich modern battery storage system? You need not worry about that as Deep Cycle System is a premium battery manufacturer in Australia with years of reliable services. The energy storage battery is vital to avoid uncertainty and grid power failure. A 12V 100Ah lithium battery ensures you have power backup for your home appliances. Most of the home appliances are 12v electric systems; that’s why the 12v battery banks are high in demand. So whatever machines you have at home they will remain in use even when grid power isn’t available. People in Australia spend more time at home after returning from work, making the energy demand rise after the afternoon and in the evening. The grid electricity is costly during peak hours which is a significant cause for a rise in electricity bills. The best solution to lower the electricity bill is to store it during low tariff hours and use it during peak hours. A 100ah lithium battery is helpful to keep grid electricity to power a load with a specific watt load. The 100AH Lithium Ion Battery can provide a backup time of roughly three and half hours for a 300 watts load. The calculation is simple, get the current value in ampere by dividing the load with battery voltage, i.e. 300/12 gives 25ampere current needs to be drawn from the battery. Now divide the battery ampere-hours by ampere, i.e. 100/4 gives four hours. If the depth of discharge is 90%, you will get 3.6 hours of backup time. Storing solar electricity is suitable for both off-grid and grid-tied solar projects. 100ah lithium ion batteries are best for a small shed where grid electricity isn’t available. Lithium batteries are dominating the power solution on a global level. From powering up cell phones to laptops, they provide a backup power source for inverters. Henceforth, lithium batteries have become a primary source to daily lives ranging from powering vehicles to providing electrical backup. Deep Cycle Systems specializes in manufacturing lithium batteries suitable for a wide range of usage. Over the years, with our extensive research and development, we have created durable, long-lasting and efficient batteries to provide trouble-free power solutions to our customers. Our Lithium batteries withstand harsh conditions and every terrain. One time investment in DCM lithium batteries gets you a long-lasting, reliable solution for all your power needs. With a wide range of lithium batteries, we at Deep Cycle Systems can cater to all your power needs, from backup to regular usage.

LiFePO4 battery has been in production for years. However, with years passing, the technology has advanced and is accessible to the ordinary person in pricing and availability. In other words, lithium batteries have refined with time, as now they are a trusty power solution. Following are the strong points as to why you should consider buying lithium batteries. Traditional lead-acid batteries require careful monitoring of acid levels, ensuring that the acid level is optimal. On the other hand, lithium batteries require no maintenance of acid levels. Hence, they essentially are trouble-free. Lithium batteries tend to charge faster as compared to a lead-acid batteries. A lithium battery can be used without charging after every use. They do not have memory function like lead-acid batteries, as they tend to lose their charging capabilities when used in-between the charges.

Safety is the number one concern for everyone, whether commercial or private. Lithium batteries are safer to use as their cells are built to withstand harsh conditions, preventing sudden fires or simply bursting into flames. 12 volt lithium battery does not have flammable fuel; hence they are safer to use. The absence of liquid acid in lithium batteries adds to safer usage. Carbon emission on planet earth is a rising environmental crisis. Henceforth, lithium batteries help reduce fossil fuel emissions by powering simple devices to vehicles.

Deep Cycle Systems specializes has a wide range of long-lasting, durable lithium batteries with increased operating capabilities. Our wide range of products, solar panels, and inverters, from lithium batteries to lithium chargers, provide a complete power solution tailored to your indoor or outdoor power needs. Deep Cycle System has outstanding services of experienced installers. We have experienced sales staff to guide you according to your needs from buying to installing our products. In addition, our team of professional technicians make the installation process smooth and trouble-free.

Solar systems are the new energy solution for powering up your house during a power outage or reducing your electrical usage in the day. The solar system is ideally combined with 12 v lithium ion batteries giving power to your home or workplace during peak hours. Electricity company providers charge you extra through smart meters, so a solar system with lithium batteries is ideal. As a result, these lithium-ion battery-powered solar systems provide backup and help keep total costs low. The energy density of lithium batteries is excellent, and the price per cycle is down. LIFEPO4 is the most efficient battery for your power solutions in renewable solar energy. Deep Cycle Systems specializes in trouble-free, low-maintenance lithium batteries for solar systems, ensuring that you never run out of electricity. Our lithium ion batteries are built to withstand harsh weather conditions while delivering excellent battery backup. Deep Cycle Systems has been in the business of providing one of the best and top-notch quality 12v 10ah lithium ion batteries for years. Your solar system will automatically switch from grid to battery power when your lithium batteries system is connected to a smart metre during peak electricity supply times. Later, when the price of a unit lowers in the evening, and the electricity demand is low, your smart solar system automatically switches to an electrical supply. As a result, this intelligent solar system aids in the reduction of energy costs while also offering a reliable power source. Plate degradation is typical with lead-acid batteries if they are not fully charged regularly. Lithium-ion batteries, on the other hand, are unaffected by setting inconsistencies. The lithium-ion batteries used in solar systems do not have to be assigned to capacity every time they are used. In fact, rather than charging them 100 per cent, it is preferable to leave them with a bit of partial charge. Furthermore, even 10ah lithium ion batteries are more efficient than lead-acid batteries for the following reasons. Have you ever observed that your cell phone stores less charge as time passes than it did when it was first purchased? This is because your phone’s ability to store charges decreases as it gets older. Similarly, the ability to store charge declines with solar batteries, but a good battery can last you considerably longer charging cycles. A lithium-ion phosphate battery, for example, promises 5000 cycles or ten years of service at 70% of its original capacity. This implies that even when your old battery is set to go out of warranty, it will only lose roughly 30% of its total capacity. The number of cycles promised by the manufacturer determines how long your solar battery will survive. If you choose a decent 12 v lithium ion batteries, your battery will most likely keep its ability to maintain a charge for a long time. Deep Cycle System is a company that specializes in solar system solutions that are integrated with lithium-ion batteries for optimal performance and long-term durability. We offer expert installation services for our durable and reliable lithium batteries to ensure a smooth energy storage solution for our valuable customers.

Deep Cycle Battery is reliable and durable when it comes to usage. These batteries perform better than the traditional lead-acid battery. Deep cycle batteries offer increased reliability, far more efficiency, and better maintenance and durability. Deep cycle batteries provide a greater good for the environment. Henceforth, more and more people have shifted to the 100ah deep cycle battery in place of other batteries. Deep Cycle Systems specializes in manufacturing durable, reliable, and safe deep cycle batteries. We are committed to providing top-notch deep cycle batteries to our valuable customers. Our deep cycle batteries offer ultimate power backup along with long-lasting service life. Deep Cycle Systems batteries are trustworthy as they provide you with safe power backup. Deep cycle batteries have significant benefits over regular lead-acid batteries. They offer more remarkable service. Following are some key benefits a deep cycle battery provides.

Deep cycle batteries output the energy continuously. In comparison, a traditional lead-acid battery fluctuates in power regularly as the charging runs down. Deep cycle batteries can stand the test they are put through. Henceforth, deep cycle batteries are widely being adopted. Environmental pollution has been a critical concern for humanity and its survival. With ecological pollution increasing every day, the reliance on fossil fuels has to be cut short. The deep cycle batteries we provide are efficient and safe for environmental usage. Deep cycle batteries are easy to carry out maintenance. Deep cycle batteries do not require regular maintenance, unlike lead-acid batteries. Therefore, these batteries are ideal for their usage in solar systems. This is because deep cycle batteries can hold the charge much longer than the traditional battery.

Deep cycle lithium battery 12v 100ah offers more excellent durability. A deep cycle battery provides much more stability than the normal car battery for starting purposes. A standard starter battery for a car or other vehicle provides peak power during starting. However, after the startup, these batteries begin charging from the alternator. Therefore, ordinary batteries are not durable in machines that require steady power for an extended amount of time. Deep cycle batteries provide durable power for more amount of time as compared to the starter battery. Deep cycle batteries offer safer, reliable, and durable power. However, they need to be charged from a dedicated deep cycle charger. A standard battery charger cannot efficiently charge your deep cycle battery while gaining the maximum output. Therefore, you require a special deep cycle battery charger for charging your battery efficiently. When purchasing a deep cycle battery, you need to perform a process known as “equalizing”. The equalizing process involves providing a low charge to your battery for an extended amount of time. The battery cells are kept in balance with each other so that during the time of using these cells, it delivers out the same output. During the usage cycles of deep cycle batteries, especially in a marine application, the equalizing process should be part of your weekly maintenance.

Deep Cycle Systems is a leading market provider for deep cycle batteries. We offer ultimate power solutions at affordable lithium ion deep cycle battery prices. We are committed to providing the best power solutions with our wide range of inverters, lithium batteries, deep cycle batteries, solar systems, solar panels, etc. Deep Cycle Systems is a top-notch provider for power solutions. We offer experienced installers for a smooth and hassle-free experience. LiPo battery stands for the full name of Lithium polymer battery. It is also referred to as a Li-Po battery or Lithium-ion polymer battery. A LiPo battery 12v uses a polymer electrolyte instead of a liquid one. This is because the polymer electrolyte delivers more specific energy than the other types of lithium batteries. The LiPo batteries are a reasonably new battery type, and their usage is more common in consumer electronic devices such as RC cars, RC planes, drones, etc. subsequently, it is evident that these batteries have been taking control and gaining popularity in the last few years among the radio control industry. LiPo or Li-Po batteries are ideal for someone who requires a longer running time while needing higher power. Deep Cycle Systems is a market leader in selling Li-Po batteries. We offer premium quality LiPo batteries to our valuable customers. Deep Cycle Systems Li-Po batteries are built to excessive relier power reliably and durably. Our batteries are built to withstand harsh weather conditions. Deep Cycle Systems LiPo batteries provide a long-lasting service life for an extended amount of time. Our batteries offer reliable performance with increased power and longer running time. Henceforth, Deep Cycle Systems LiPo batteries are ideal for usage in your drones, RC cars, RC planes, and other such devices.

LiPo batteries come with a wide range of benefits. However, it is up to the user to decide if the benefits offered by LiPo batteries outweigh the drawbacks. For the majority of the people, benefits matter and serve more as compared to the disadvantages. LiPo batteries are reliable and safe to use as long as you take care of them, handle them correctly and follow the rules. LiPo battery size depends upon the amount of power you require. Bigger the capacity more flight or running time your battery will deliver. However, as the size increase, so does the weight. Therefore it is always recommended to check with the instruction manual of our device. This helps in figuring out the maximum battery size you can run safely. Determining the discharge rate ideal for your usage device from LiPo battery is crucial yet often overlooked. A battery with too low of a discharge rate can damage the battery quickly. This can lead to an insufficient voltage supply to ensure the smooth running of, let’s say, your RC car or drone. The higher the battery has discharging rate, the heavier it is. Henceforth, if you are using a battery that has a high discharge rate, it is more likely that you just are carrying extra weight around yourself that you don’t need. This increased weight ultimately shortens the running time of your device being powered by the LiPo battery. Deep Cycle Systems offers expert installation services of our energy solutions. Our team of expert installers makes the installation process seamless and hassle-free. Henceforth, when you select Deep Cycle Systems for all your energy solution needs, we make sure you get a premium experience from purchasing to delivery at your doorstep and fast installation. Deep Cycle Systems is a market leader for delivering premium energy solutions to our valuable customers. With years’ worth of experience in the field, our products are developed by research and development. Deep Cycle Systems delivers long-lasting and reliable power solutions.

Technological advancements in 12vdc deep cycle battery have provided cars & SUVs with more performances under the wheels while extending the travelling range. In addition, Lithium batteries being improved over the years have become more cost-effective and sustainable, ultimately becoming affordable for the consumer. Deep Cycle Systems is a top-grade lithium battery manufacturer. We provide excellent battery support to your vehicles ranging from cars to SUVs. Our lithium batteries last longer while delivering performance and durability. In addition, the battery produced at Deep Cycle Systems is highly effective. Our battery has a minimum discharge, thus enough power for your vehicle to function if it sits idle for an extended amount of time. On the other hand, our lithium battery is solid for daily usage as they are resistant to harsh weather conditions while working at its total capacity. When it comes to a car battery, several types of batteries are being used in cars. Therefore, technological advancement in the chemistry of lithium batteries has provided various kinds among it. Li-ion is the most common and widely adapted type of lithium battery. It is the most advanced type used in many devices and places, from powering cellphones to laptops, cameras, etc. Like Li-ion batteries, they also power bigger electrical appliances such as inverters and provide backup in RV vehicles. Lithium-ion has the most stabilized chemistry among its types, storing more charge and leading to more backup capacity. This lithium battery type is also known as Zebra battery. In Africa, these Zeolite battery research was used in some concept cars and buses for urban transportation. Molten Salt batteries can resist overcharging and over-discharge. The lithium battery of molten salt type is immune to lower temperatures; hence, robust in harsh conditions. However, the disadvantages this type brings to the table are increased internal temperature as high as 270 °-350 °C. Henceforth these batteries are unsafe for their usage in electric or fossil fuel-powered vehicles.