Slim Line Lithium Battery for Heavy-Duty Diesel Engines

The DCS slim line lithium battery is built for tough jobs, like starting big diesel engines in UTEs and dual-cab vehicles. It has a powerful 1200 LCA (Cold Cranking Amps) that helps your engine start quickly, even in hard conditions. The battery is super safe, designed to avoid explosions and leaks, so it’s perfect for rough and demanding work.

This battery is built to last a long time and works smoothly every time you need it. It’s a great choice if you need a strong and reliable power source for your vehicle.

Slim Line Lithium Battery for Versatile Outdoor Applications

The DCS slim line lithium battery is made to handle lots of outdoor uses. Whether you’re camping, traveling in a caravan, or just exploring, this battery will keep you powered up. It’s slim and small, so it fits into tight spaces, but it still gives you top-notch performance. It’s strong and dependable, so you can enjoy your adventures without worrying about losing power.

Here are some important features of the DCS slim-line lithium battery:

- Lightweight: Weighs only 31.50 kg, making it easy to handle.

- Handles Extreme Temperatures: Works in temperatures from -25°C to 80°C.

- Long Warranty: Comes with a 5-year unlimited cycle warranty for your peace of mind.

- Lasts a Long Time: Can go through 4000 cycles at full discharge and still keep at least 80% of its capacity.

This battery is a great option for anyone looking for a strong and reliable power solution for outdoor use.

DCS 120Ah Battery – Strong and Reliable for Tough Jobs

When you need a battery you can count on, the DCS 120Ah battery is a smart choice. It’s built to handle tough conditions, like marine environments, off-road vehicles, and industrial work. The battery is tough enough to deal with constant movement and bumps. Whether you’re using it for a home solar power system or powering an off-grid setup, this battery will give you steady and reliable energy.

Key Features of the DCS 120Ah Battery

- No Memory Effect: Our 120Ah battery keeps its full capacity even if you charge it before it’s fully drained.

- Energy Efficient: Great for saving extra energy from solar panels to use later.

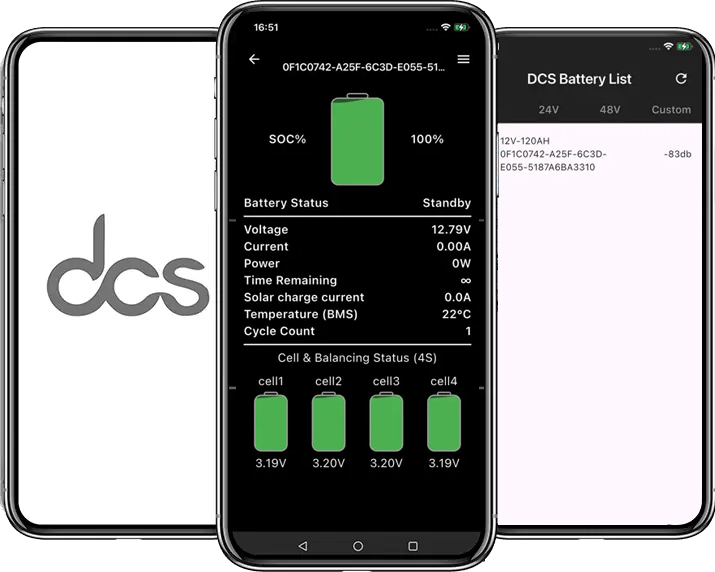

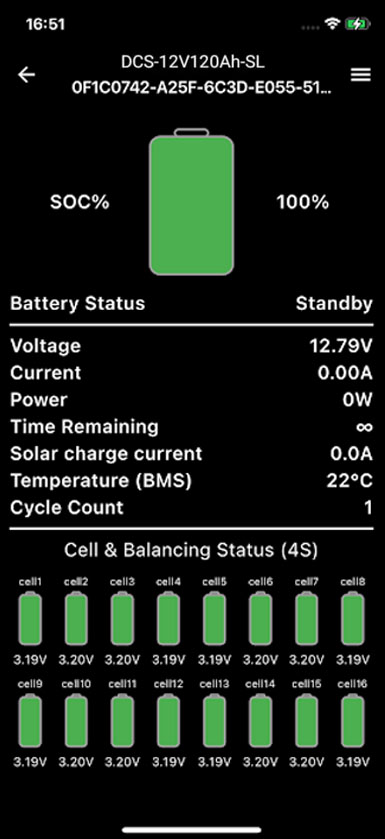

- Easy to Monitor: The DCS LFP Mobile App shows you the battery’s temperature, charge level, and more in real time.

- Built to Last: Comes with a 4-year replacement warranty, so you know it’s a good investment.

If you choose a DCS 120Ah battery, you’re getting a durable and advanced product that helps you save money and energy over time.

Safe Transport with the 100Ah Slimline Lithium Battery

The DCS 100Ah slimline lithium battery isn’t just powerful—it’s also built to be transported safely. It has a special UN 38.3 certification, which means it’s passed many safety tests. These tests check how well it handles things like changes in altitude, extreme temperatures, vibrations, and sudden impacts. The battery is proven to handle being shipped by air, sea, or land without any problems.

When you choose this battery, you can feel safe knowing it won’t cause fires or leaks during transport.

Safety Testing for the 100Ah Slimline Lithium Battery

The DCS 100Ah slimline lithium battery goes through many tests to make sure it’s safe to move around. These tests prove it can handle tough situations while being transported. Here’s what it goes through:

- Altitude Tests: Makes sure it works well at high elevations.

- Temperature Tests: Checks that it stays stable in very hot or very cold conditions.

- Bump Tests: These tests check if the battery can handle shakes and bumps while being moved.

- Drop Tests: Makes sure the battery won’t break or stop working if it gets dropped or hit.

- Safety Checks: Shows proof that the battery is safe and meets all the rules.

When you pick the DCS 100-Ah slimline lithium battery, you’re getting a battery that’s been checked for safety and works well. It’s a smart choice if you need a strong and reliable power source.

Stay Prepared with a 120 Ah Lithium Battery

The endless innovative solutions in construction and technology demand the DCS 120 Ah lithium battery. With its precise lithium iron phosphate chemistry, this modern-day battery stores massive energy while compacting. Now, energy will not be an issue while camping, in emergencies, or even living off the grid. The benefits do not end there; unlike other lead-acid batteries, with the DCS 120-Ah lithium battery, active maintenance and constant upkeep are eliminated. Now, when you require energy, it will be there on demand.

Moreover, the DCS 120-Ah lithium battery can be used in extreme climates due to its outdoor and indoor compatibility. Now, your energy partner will be with you on every excursion and hold your trust in ensuring a constant power supply. There is no need for you to worry about power outages, needing a solution and reliable safety features, so go outdoors without care. When partnering with DCS, you are guaranteed cutting-edge quality.

Effortless Power Backup with 120 Ah Lithium Battery

With DCS’s 120 Ah lithium battery, providing reliable power backup is simple. Here are the key benefits:

- Considerably lightweight, allowing for easy transport and versatility.

- Special construction allows quick charging, minimising downtime.

- Designed for long cycle life and sustainability.

- Can be transported and handled safely due to UN 38.3 certification.

When you invest in the DCS 120-Ah lithium battery, you invest in an effective power solution that expands your capability for preparedness, whether in the office, at home, or on the move. That’s great because you can have peace of mind knowing that the energy storage is dependable whenever you need it.

Slimline Lithium Battery 100ah – Compact and Reliable Power Solution

The slimline lithium battery 100ah is a lightweight, compact, and flexible battery solution for many energy systems. Its groundbreaking design allows consumers to take advantage of its vast power capacity while promising low volume. This makes it suitable for both domestic and industrial use.

DCS continuously seeks to provide cutting-edge products that stand by national and international safety standards so that the slimline lithium battery 100-ah is efficient, effective, and reliable.

Safety Certified Slimline Lithium Battery 100ah for Versatile Applications

Safety-approved slimline lithium battery 100ah easily rests on users’ minds regarding the global transportation guidelines, which are critical for users with safety concerns. This battery passes all enveloping tests from the UN 38.3 guidelines, ensuring a minimal risk during transport.

- Designed for external and mobile applications

- Eco-friendly with low discharge rates

- Perfect for emergency backups

- Strong protection against thermal events.

DCS believes that safety should always come first in transportation so consumers have peace of mind concerning the slimline lithium battery 100-ah’s quality standards. This pursuit of power and DCS’s commitment to expand the possibilities of safety in battery technology reveals their strong adherence to prescription power and safety limits.

Experience Reliable Performance with the 120 Ah Lithium Battery from DCS

When you need a dependable source of power that can keep up with your modern energy demands, the 120 Ah lithium battery by Deep Cycle Systems stands out. Whether you’re building an off-grid setup, powering your 4WD, or supporting a solar array, this battery delivers consistent output without the hassle of ongoing maintenance or voltage fluctuations.

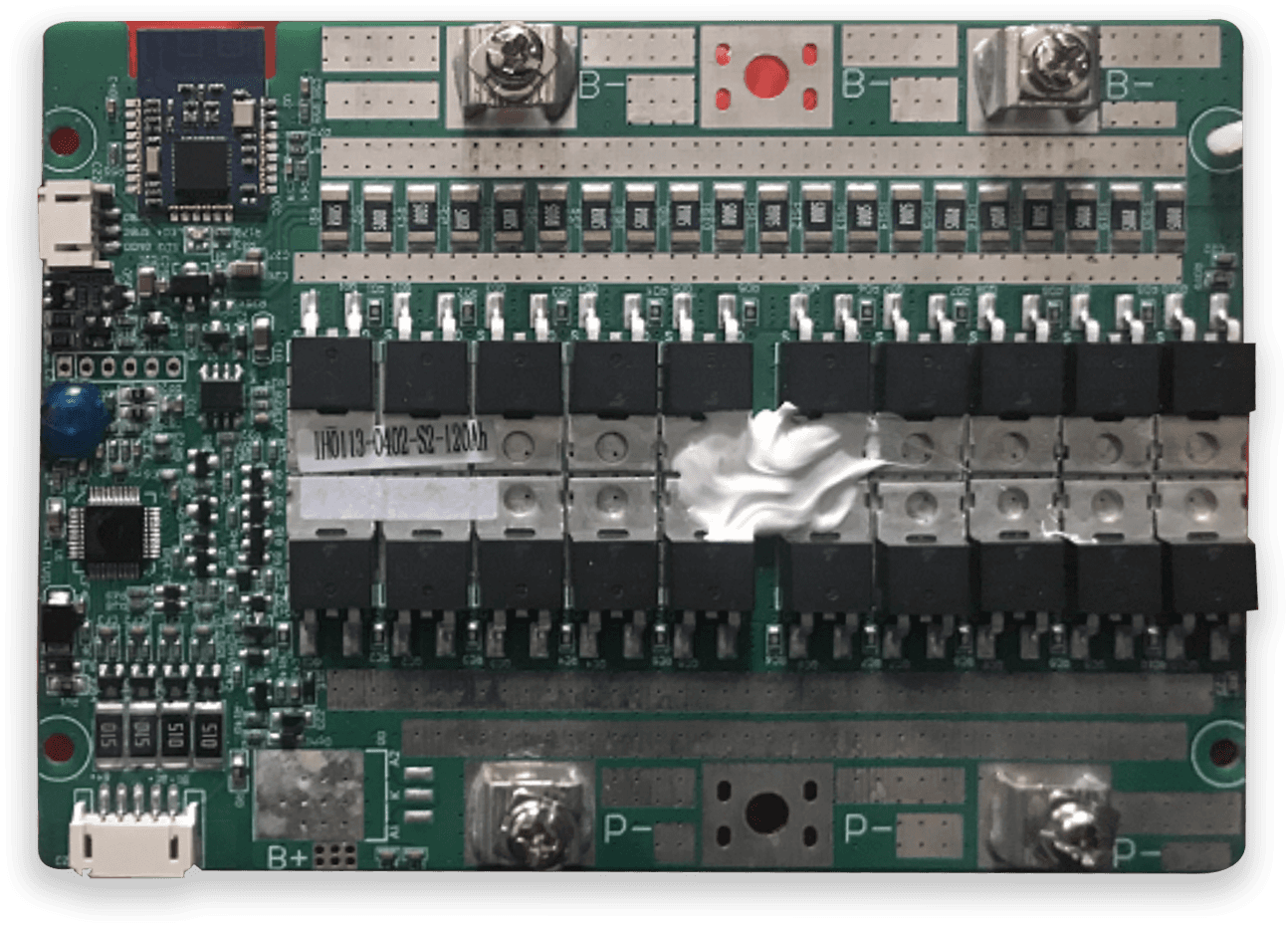

What sets this battery apart is its internal construction—premium cylindrical LiFePO₄ cells combined with DCS’s proprietary BMS software ensure safe and steady performance across all conditions. It’s made to last through thousands of deep cycles without capacity fade while staying lightweight, compact, and efficient. With the 120 Ah lithium battery, you choose advanced energy storage built for Australia’s most demanding environments.

How the 120 Ah Lithium Battery Powers Off-Grid and Backup Systems

The 120 Ah lithium battery is the ideal solution for users who need independence from the grid or a reliable backup system.

- Retains over 80% capacity after 4000 full discharges

- Compatible with solar, DC-DC, and AC chargers

- Sealed, maintenance-free design ideal for indoor or mobile use

- Fast recharge capability reduces downtime during cloudy days

- BMS ensures protection against overcharge, heat, and short circuits

If you’re investing in energy independence, the 120 Ah lithium battery provides peace of mind with every charge.

Long-Lasting Energy in a Compact Design with 120Ah Lithium Technology

In tight installations and mobile setups, size and weight matter. The 120Ah lithium battery from DCS is engineered to deliver high-capacity energy storage without taking up unnecessary space. Whether fitting it into a drawer system in a van or behind a seat in your 4WD, this battery allows you to go further—without adding bulk or complexity.

Made with lithium iron phosphate chemistry, this battery holds up under heat, vibration, and deep cycling. It’s the kind of product you install once and count on for years. The 120Ah lithium battery offers serious runtime, rapid recharge, and full-depth discharge without the typical wear you’d expect from older technologies.

Where the 120Ah Lithium Battery Excels in Modern Mobile Setups

Perfect for travel and remote operations, the 120Ah lithium battery supports many off-grid needs.

- Slim, lightweight design fits in vehicles, trailers, and utes

- Handles daily cycling without performance drop

- Works with inverter systems to power appliances on the go

- Compatible with solar charging and vehicle alternators

- Built tough for harsh Aussie terrain and temperature swings

When you’re always on the move, the 120Ah lithium battery allows you to explore without worrying about your power supply.

Built to Last: The Durable and Powerful Lithium 120Ah Battery

The lithium 120Ah battery is built for users who demand more life, reliability, and performance. Backed by military-grade cell chemistry and engineered by Deep Cycle Systems, this battery is challenging and extremely intelligent. It adapts to high-drain loads and fast-changing conditions, ideal for residential energy systems and mobile rigs.

Its slimline, low-resistance structure means that the battery delivers clean, stable voltage even under full load. It’s safe, silent, and rugged, with advanced BMS protection against overcharging, temperature extremes, and short circuits. The lithium 120-Ah battery is a serious solution for anyone building a reliable, high-capacity energy system.

When to Choose a Lithium 120Ah Battery over Conventional Options

There are many reasons to upgrade to a lithium 120Ah battery, especially when compared to AGM or lead-acid alternatives.

- Delivers more usable energy per cycle with less weight

- Maintains voltage stability even under high loads

- Can be fully discharged without long-term damage

- It lasts up to 4x longer than traditional battery types

- Requires no water top-ups, venting, or terminal checks

If you want a battery that performs, lasts, and protects itself over time, the lithium 120-Ah battery is a smart, long-term investment.

Smart Energy Storage with the Lithium Ion Battery 120Ah

The lithium ion battery 120Ah from Deep Cycle Systems is designed to simplify energy storage without sacrificing power or performance. Whether building a solar system or prepping for outages, this battery gives you more usable energy with every cycle. Thanks to LiFePO₄ cell chemistry and our proprietary BMS, it delivers clean, stable output—so your devices and appliances stay protected no matter the conditions.

This battery stands out in backup and solar applications because of its safety, efficiency, and long-term cost-effectiveness. The lithium-ion battery 120Ah charges quickly hold a charge for long periods and requires zero maintenance. That means less downtime, less worry, and more energy where and when you need it.

Why the Lithium Ion Battery 120Ah is Ideal for Solar and Emergency Power

Do you need consistent power during blackouts or cloudy stretches? The lithium ion battery 120Ah is your reliable energy partner.

- Holds full charge capacity even after extended storage

- Discharges safely down to 100% without damage

- Rapid recharge from solar panels or AC input

- BMS ensures protection against surges and thermal risks

- Compact enough to fit tight off-grid or utility installs

When energy matters most, the 120ah lithium-ion battery helps you stay powered, whether you’re living off-grid or riding out a storm.

Lightweight and Efficient 120 Lithium Battery for Mobile Power

Designed with weight, size, and usability in mind, the 120 lithium battery is ideal for mobile power setups. If you travel, camp, or work remotely, you know that a heavy, bulky battery just won’t cut it. This one’s compact, easy to carry, and still delivers high energy capacity—perfect for 4WDs, vans, or backup systems.

Deep Cycle Systems has engineered this battery to work in harsh environments without breaking a sweat. It doesn’t fade under load, doesn’t need maintenance, and integrates easily with your solar, alternator, or mains charging sources. The 120 lithium battery makes your power system more flexible and less demanding.

Using a 120 Lithium Battery in Portable and Residential Applications

The 120 lithium battery is a power solution ready to adapt from portable kits to permanent builds.

- Small footprint fits into tight utility drawers or behind seating

- Delivers smooth voltage for electronics and appliances

- Supports both 12V mobile gear and home backup setups

- Lightweight casing reduces strain on travel systems

- Pairs well with solar regulators and DC-DC chargers

Whether at home or off the beaten path, the 120 lithium battery gives you quiet, reliable power wherever you go.

Maximise Output with the High-Capacity 120 Amp Lithium Battery

If your energy system requires high output and fast response, the 120 amp lithium battery is up to the challenge. Designed to support large inverters, tools, and devices with heavy surge demands, this battery performs well under pressure without sacrificing safety or cycle life.

Thanks to its advanced BMS and high-discharge cell configuration, it delivers consistent power even when pushed to its limits. The 120-amp lithium battery is ideal for setups where a typical battery might falter—think mobile workshops, emergency gear, or off-grid installations that run heavy equipment.

Applications That Push the Limits of the 120 Amp Lithium Battery

Need serious performance? The 120 amp lithium battery is made for it.

- Handles power tools, pumps, and induction loads without voltage drop

- Delivers strong surge performance for high-draw devices

- Ideal for off-grid solar systems with large inverter setups

- Operates in high temps and rough terrain without degradation

- It is fully sealed, so it’s safe to install in compact or enclosed spaces

From trades to travel, the 120 amp lithium battery ensures your system has the power to perform under pressure.

Energy You Can Rely On with 120Ah Deep Cycle Battery Technology

When you need stable, long-lasting power for your off-grid system or backup energy supply, the 120Ah deep cycle battery is a trusted choice. It’s designed to release steady voltage over long periods, perfect for continuous-use environments like solar-powered homes, cabins, caravans, or mobile workstations. At Deep Cycle Systems, we’ve built this battery to thrive in tough Australian conditions—heat, movement, and load variations don’t faze it.

With premium LiFePO₄ cell chemistry and an intelligent BMS, this battery delivers energy efficiently and safely over thousands of charge cycles. There are no fumes, no maintenance, and no sudden drop in performance—it just works. The 120Ah deep cycle gives users peace of mind, whether off the grid full-time or relying on backup systems during outages.

Why a 120Ah Deep Cycle Battery is the Smart Choice for Continuous Use

A 120Ah deep cycle battery offers long-term reliability without compromise for systems that cycle energy daily.

- Handles full discharges and recharges without damaging cell health

- Supports solar charge controllers, inverters, and hybrid setups

- Compact enough for RVs, boats, or home battery banks

- Stays stable even in hot, dusty, or high-vibration conditions

- There is no memory effect, no top-ups—just consistent performance

From daily use to seasonal reliability, the 120Ah deep cycle battery keeps your setup running strong without constant attention.

Rugged and Resilient: The 120Ah Deep Cycle Battery by DCS

The 120Ah deep cycle battery from Deep Cycle Systems isn’t just a power source—it’s a commitment to quality, performance, and safety. Designed using high-grade cylindrical lithium cells and our GEN3 BMS technology, it delivers steady, efficient power for high-demand setups. This battery won’t let you down, whether on the road, on the water, or completely off-grid.

What makes this battery stand out is how well it performs under pressure. Unlike traditional lead-acid units, it maintains voltage even under heavy draw, doesn’t lose capacity when unused, and doesn’t require active maintenance. The 120Ah deep cycle battery is engineered for resilience in both environmental and electrical challenges.

Where the 120Ah Deep Cycle Battery Fits into Modern Solar Systems

Built for integration, the 120Ah deep cycle battery plays well with today’s smart energy setups.

- Works with hybrid, off-grid, or grid-tied solar systems

- Stores solar energy for night-time or emergency use

- Supports high-efficiency inverters and battery monitors

- Slim enough for discreet installation, strong sufficient for full-load use

- Perfect for residential, mobile, marine, and industrial use

If you’re upgrading or designing your energy system for reliability, the 120Ah deep cycle battery is a powerful, future-ready solution that keeps you in control.

”Close”