DEEP CYCLE SYSTEM SPECIALISED LITHIUM-ION BATTERY

Deep Cycle System is a top-notch power solution provider. We at Deep Cycle System offer various products ranging from batteries to solar systems, solar chargers, solar controllers, etc. Pricing is a critical factor in any purchase decision. Deep Cycle System offers reasonable pricing on excellent products. Our products are affordable along with maximum durability. Deep Cycle System delivers long-lasting power solutions for your off-grid and on-grid usage.

Deep Cycle system is equipped with a highly skilled team of installers. The product installation and guidance is more straightforward and seamless. In addition, Deep Cycle Systems has excellent sales services for our valuable customers as we are committed to providing the best product and after-sales services to our clients. Shop with us for a premium experience for your power solutions.

Largest Deep Cycle Battery

A largest deep cycle battery for your home is the best way to store solar energy and reduce electricity bill. We have deep cycle battery packs that you can use for your home to store solar energy and reduce electricity bill. Why go through all that hassle? Just drop by our online store and order a 200ah battery pack to keep at your home!

What Could I Get from a Largest Deep Cycle Battery?

If you have ever wondered what is a Deep Cycle Battery and what could you get from a largest deep cycle battery for your home? A deep cycle battery is a rechargeable battery that can be drained and recharged many times. It is designed to be discharged even below 50% of its capacity hundreds of times over the life of the battery.

Whereas other common batteries are only meant to be used until they half of their capacity. The most popular use for this type of technology would be in golf carts, forklifts and scooters but there are many other uses for these devices as well.

We have Largest Deep Cycle Battery packs that you can use for your home to store solar energy and reduce electricity bill. You can get a battery with a higher amp hour rating, but it will be heavier and more expensive. On the other hand, you can get a battery with a lower amp hour rating, but it will be lighter and cheaper.

200ah Deep Cycle Battery for Marine applications

200ah Deep Cycle Battery for Marine applications

You can use a 200ah Deep Cycle Battery as a starting battery, but it will not last very long. Deep cycle batteries are designed to provide steady power over extended periods of time. A starting battery is designed to provide bursts of high current (for example, when you start your car engine). When used in this way, the life expectancy of a 100ah deep cycle battery would be about 25-30 starts before it needs replacing.

A 200Ah deep cycle marine battery can also be used for power for other devices on your boat such as lights and electronics. These devices can draw up to 10 amps continuously over hours or days at a time so this type of application is ideal for larger capacity batteries like those found on boats with multiple cabins or people living aboard full time who want to run air conditioners etcetera all day long without worrying about recharging or running out of power mid-cruise!

200ah Deep Cycle Battery for under bonnet

A 200ah deep cycle battery is the best choice for under bonnet, super capacitors and hybrid vehicles. This type of battery is also called as “deep cycle” because it has a larger capacity than the traditional starting battery. It can be used for home solar power systems, electric golf carts and forklifts.

The first thing to know about this type of battery is that it has a much higher energy density than other types of batteries in its class (e.g., starting and deep cycle). This means you will get more out of every single amp hour compared to other types available on the market right now!

Role of Deep Cycle System Battery Ah Capacity

Role of Deep Cycle System Battery Ah Capacity

Deep Cycle Systems (DCS), a leader in battery technology in Australia, emphasises the importance of ampere-hour (Ah) capacity in deep cycle batteries. The Deep Cycle System, Battery Ah capacity, is a pivotal measure, indicating the amount of energy the battery can store and deliver over time. For applications like renewable energy systems or backup power, a higher Ah means a longer-lasting energy supply. DCS’s range of deep cycle batteries, with varied Ah capacities, cater to diverse energy needs. They ensure reliable performance, even in demanding situations, making them an essential component in off-grid and auxiliary power setups.

With DCS’s commitment to quality, their deep cycle batteries with high amp hour battery capacity stand out. These batteries offer a robust solution for sustained power delivery. The higher the Ah rating, the more energy can be stored, translating into longer run times for devices and systems. This makes DCS batteries ideal for situations requiring consistent power over extended periods, such as in remote locations or emergency power systems. Their batteries are designed to withstand repeated charging and discharging, ensuring durability and efficiency.

Best Deep Cycle System Battery for Electricity Backup

When it comes to electricity backup, the best Deep Cycle System battery packs in Australia are second to none. Their batteries are engineered for resilience and longevity, providing dependable backup power during outages. This reliability is crucial for critical systems and households alike, ensuring uninterrupted power supply. DCS batteries are designed to seamlessly integrate with existing power systems, offering a hassle-free backup solution. With their advanced technology and superior build, these batteries are an investment in peace of mind and convenience.

Buy A Reliable Backup Energy Storage

Buy A Reliable Backup Energy Storage

DCS’s deep cycle batteries are distinguished by their deep discharge capability, making them perfect for backup applications. They can maintain power over extended periods, which is essential during prolonged outages. The robust design ensures they can handle the rigours of frequent power fluctuations and deep discharges without losing efficiency. For consumers seeking a top-notch electricity backup option, DCS’s deep cycle batteries are the go-to choice. They offer a blend of performance, durability, and reliability that is hard to match, making them an ideal choice for any backup power requirement.

200 Amp Lithium Battery for On-Grid Solar Power System

Deep Cycle Systems (DCS) has revolutionised on-grid solar power systems with their 200 amp lithium battery packs. These batteries are designed to maximise energy storage from solar panels, enhancing the efficiency of solar power systems. The high-capacity 200 amp lithium batteries are ideal for on-grid applications, storing excess solar energy for use during peak demand or low sunlight periods. This not only reduces reliance on the grid but also lowers electricity bills. DCS’s lithium batteries are lightweight, compact, and boast a longer lifespan compared to traditional batteries.

200 Amp Lithium Battery Ensures Reliable Energy Backup Option

200 Amp Lithium Battery Ensures Reliable Energy Backup Option

In an on-grid solar power setup, DCS’s 200 amp lithium batteries play a critical role in energy management. They provide a stable and reliable energy source, ensuring that households and businesses have access to solar power even when the sun isn’t shining. The batteries’ high capacity allows for greater energy storage, making solar systems more efficient and effective. Additionally, DCS’s lithium batteries require minimal maintenance, adding to their convenience. Their integration into on-grid solar systems represents a smart investment in sustainable energy, aligning with Australia’s growing focus on renewable resources.

Lithium 200ah Battery for Off-Grid Solar Power System

Deep Cycle Systems (DCS) offers the Lithium 200ah battery, a cornerstone for off-grid solar power systems. This battery is expertly designed to store and deliver energy effectively, ensuring that off-grid setups are powered efficiently. Its 200ah capacity allows for substantial energy storage, making it ideal for locations without grid access. With this battery, users can harness solar energy during the day and utilise it at night or during low sunlight periods, enhancing the autonomy of off-grid solar systems.

Maximising Solar Energy Utilization

Maximising Solar Energy Utilization

The DCS Lithium 200ah battery not only stores energy but also optimises its usage. This is crucial in off-grid locations where every watt counts. Its efficient energy management ensures that solar power is utilised to its fullest potential, minimising waste and maximising availability.

Lithium Ion Battery 200ah has 12.8v Nominal Voltage – What is Nominal Voltage Capacity in a Battery?

The Lithium Ion Battery 200ah capacity and 12.8v nominal voltage, like those provided by Deep Cycle Systems (DCS), is a powerhouse of efficiency. Nominal voltage is essentially the default operating voltage of the battery. In this case, 12.8 volts is the average voltage at which the battery runs under normal conditions. It’s a critical spec, as it determines the compatibility of the battery with the devices it powers.

Understanding Battery Compatibility and Performance

Knowing the nominal voltage of a battery is key to matching it with appropriate applications. For DCS’s 200ah lithium-ion battery, the 12.8v nominal voltage indicates its suitability for a wide range of solar power systems and electronic devices. This compatibility ensures optimal performance and longevity of both the battery and the connected equipment.

Reliable DCS 200 Amp Lithium Ion Battery Provides Exactly 200A

The 200 Amp Lithium Ion Battery from Deep Cycle Systems (DCS) is a testament to reliability and precision. Engineered to deliver exactly 200 amps, this battery is a reliable power source for a variety of applications. Its precise amperage delivery is essential for devices and systems requiring consistent and accurate power input, making it a preferred choice for both professionals and hobbyists alike.

Precision Power for Critical Applications of 200 Amp Lithium Ion Battery Packs

Precision Power for Critical Applications of 200 Amp Lithium Ion Battery Packs

Accuracy in power output is crucial, and the DCS 200 Amp Lithium Ion Battery excels in this aspect. Its ability to provide exactly 200A is particularly beneficial for sensitive equipment that demands steady and precise power input. This level of precision ensures the efficient and safe operation of connected devices, underlining the battery’s role as a vital component in critical power systems.

Li Ion Battery 200Ah Vs Lead-Acid Battery – Capacity Retention Ability

When comparing a Li ion battery 200Ah to a lead-acid counterpart, the difference in capacity retention ability is stark. Li-ion batteries, like those offered by Deep Cycle Systems (DCS), retain their capacity much longer than lead-acid batteries. This means they can deliver close to their full capacity even after hundreds of charge cycles. In contrast, lead-acid batteries tend to lose their capacity quickly, necessitating more frequent replacements. The superior capacity retention of Li-ion batteries makes them a more reliable and cost-effective choice in the long run.

Sustained Performance Over Time

Li-ion batteries maintain their performance over a longer period, making them ideal for applications where consistent power delivery is crucial. With a 200Ah Li-ion battery, users experience a consistent energy output, whereas lead-acid batteries might show a decline in performance as they age. This aspect is vital for systems requiring a stable power supply.

200 Amp Hour Lithium Battery is A Good Replacement Option for an AGM Battery

A 200 amp hour lithium battery is an excellent replacement for an AGM (Absorbent Glass Mat) battery, especially in terms of efficiency and longevity. Deep Cycle Systems (DCS) offers lithium batteries that are lighter, have a higher energy density, and charge faster than AGM batteries. This not only makes lithium batteries more convenient to use but also more cost-effective in the long term due to their extended lifespan and reduced maintenance needs.

Enhancing System Efficiency and Usability

Enhancing System Efficiency and Usability

The switch to a 200Ah lithium battery from an AGM battery can significantly improve the efficiency of a power system. Users benefit from faster charging times and a more extended range of operation, which is particularly beneficial for mobile or remote applications. The lightweight nature of lithium batteries also adds to the ease of installation and handling, making them a user-friendly option.

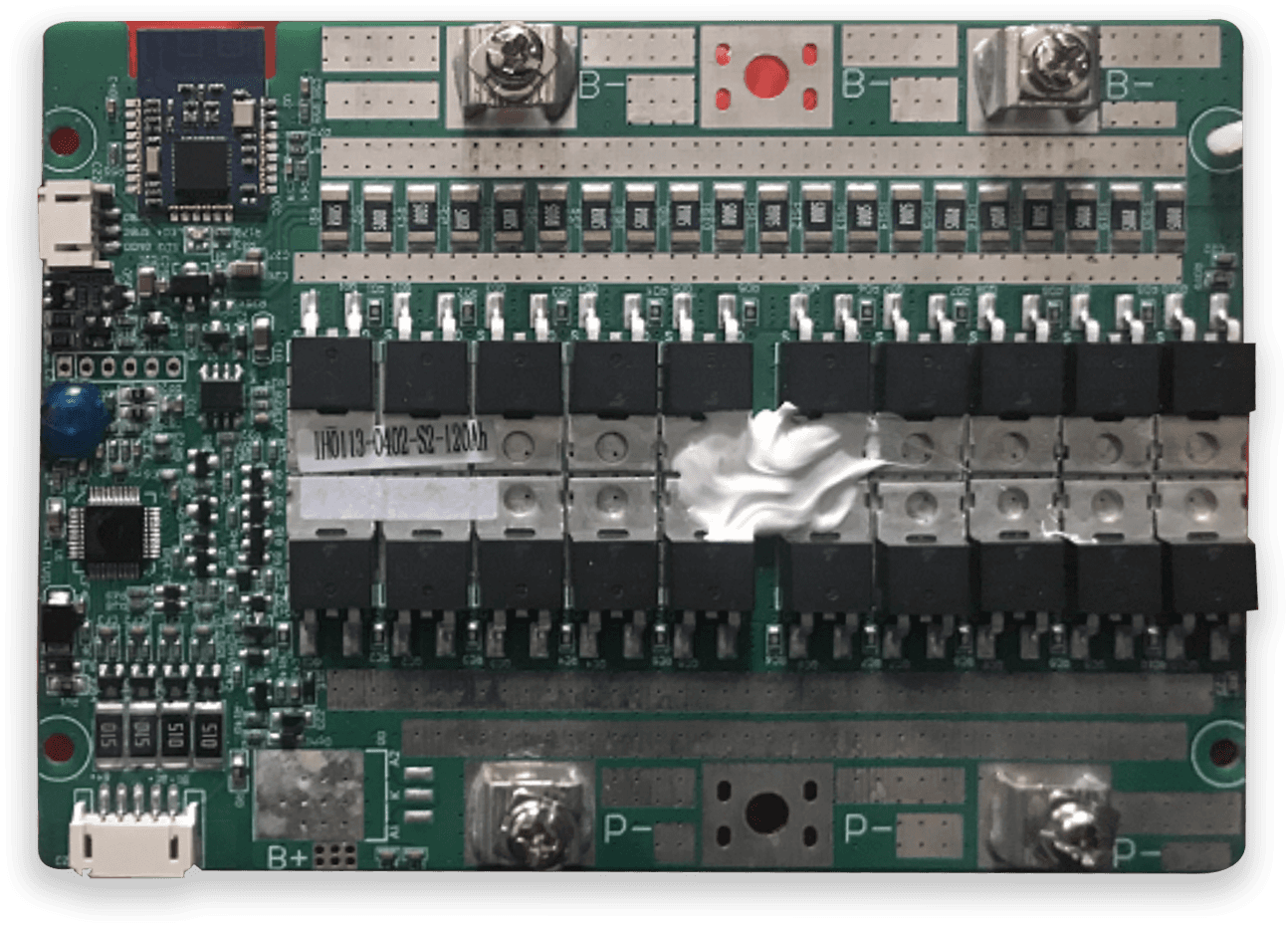

DCS 200ah Lithium Ion Battery With Active Cell Management System for Battery Cell Protection

The DCS 200ah Lithium Ion Battery stands out with its advanced Active Cell Management System. This system ensures each cell within the battery is monitored and balanced, promoting longevity and safety. It protects the battery from common issues such as overcharging, deep discharge, and temperature fluctuations. This active management contributes to the overall health and efficiency of the battery, ensuring it operates at its best throughout its lifespan.

Prolonging Battery Life and Ensuring Safety

The inclusion of an Active Cell Management System in DCS’s 200ah Lithium Ion Battery not only prolongs the battery’s life but also enhances its safety. This system actively prevents conditions that could lead to battery damage or failure, offering peace of mind to users. It’s an essential feature for those relying on consistent and safe power in various applications, from renewable energy systems to critical backup power sources.

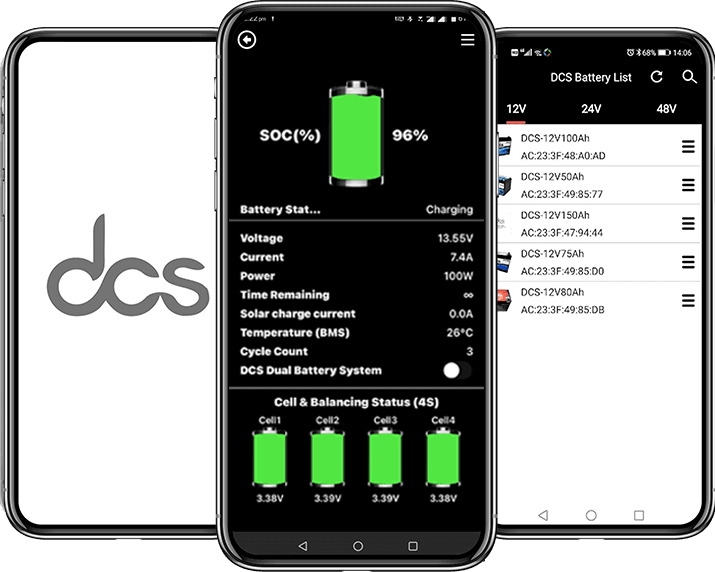

200ah Slimline Lithium Battery – Latest GEN3 BLE Battery Management System

Deep Cycle Systems (DCS) introduces the 200ah Slimline Lithium Battery, equipped with the latest GEN3 BLE (Bluetooth Low Energy) Battery Management System. This cutting-edge technology offers real-time monitoring and control via a Bluetooth connection, enhancing the user experience. The GEN3 BLE system ensures efficient operation and maximises the battery’s lifespan by actively managing charge and discharge cycles, temperature, and overall battery health. Its slimline design makes it an ideal choice for space-constrained applications without compromising power or efficiency.

Advanced Control and Monitoring for Optimal Performance

The GEN3 BLE Battery Management System in the 200ah Slimline Lithium batteries allows users to effortlessly monitor and adjust settings through their smartphones. This level of control and transparency ensures that the battery operates within optimal parameters, thereby enhancing its performance and reliability, especially in critical applications where battery health and status are paramount.

Slimline Lithium Battery 200Ah Active Cell Management Integrated Circuit Can Handle 3.7A Dynamic Movement Per Channel

Slimline Lithium Battery 200Ah Active Cell Management Integrated Circuit Can Handle 3.7A Dynamic Movement Per Channel

DCS’s Slimline Lithium Battery 200Ah stands out with its Active Cell Management Integrated Circuit capable of handling 3.7A dynamic movement per channel. This feature ensures that each cell within the battery is individually managed for current flow, enhancing the battery’s efficiency and longevity. The ability to handle 3.7A per channel means the battery can smoothly adapt to varying power demands, making it exceptionally reliable for a range of applications.

Enhanced Efficiency and Power Stability

The Active Cell Management system in the Slimline Lithium batteries of 200Ah capacity plays a crucial role in maintaining power stability and efficiency. By managing dynamic movement at 3.7A per channel, the battery provides a consistent energy output, even under fluctuating load conditions. This makes it an ideal power source for systems that experience varied energy demands, ensuring an uninterrupted and stable power supply.

Best 200ah Lithium Battery –Thermal Management Ensure the Boards Remain Reliable In Harsh Environments

The best 200ah Lithium Battery by DCS is designed with an exceptional thermal management system, ensuring the boards remain reliable in harsh environments. This feature is critical for maintaining the battery’s integrity and functionality in extreme temperatures. The thermal management system actively regulates the temperature, safeguarding the battery from overheating and cold-induced inefficiencies. This makes the battery robust and suitable for use in a wide range of environmental conditions.

Optimal Performance in Diverse Conditions

Optimal Performance in Diverse Conditions

The advanced thermal management system in DCS’s 200ah Lithium Battery plays a pivotal role in ensuring the battery’s reliability across various environmental conditions. Whether in the scorching heat or freezing cold, the battery maintains its efficiency and performance. This adaptability makes it the ideal choice for applications in challenging climates, where consistent power delivery is crucial.

200ah Lithium Battery Slimline CMS Able to Withstand Maximum Current and Thermal Loads for Long Term Reliability

Our 200ah Lithium Battery Slimline technology features a Slimline Cell Management System (CMS) engineered to withstand maximum current and thermal loads. This robust design ensures long-term reliability, which is crucial for applications requiring consistent and stable power. The CMS actively manages the battery’s load distribution and thermal conditions, preventing overloading and overheating. Such capabilities make the battery exceptionally durable and able to handle high-demand applications while maintaining optimal performance and longevity.

Enhanced Durability for High-Demand Applications

Enhanced Durability for High-Demand Applications

The resilience of the Slimline CMS in DCS’s 200ah Lithium Battery is particularly advantageous in high-demand scenarios. It ensures that the battery can consistently deliver power without compromising its structural integrity or performance. This durability is a key factor for users who need a reliable power source in environments where the battery is subject to continuous high loads and variable temperatures.

DCS Lithium 200ah Battery Packs are Designed to Absorb Severe Vibration Abuse

DCS’s Lithium 200ah Battery Packs are specifically designed to endure severe vibration abuse, a testament to their rugged construction. This feature is crucial for applications in mobile environments or settings prone to constant movement and jostling. The batteries’ ability to absorb and withstand vibrations ensures their continuous operation and longevity in challenging conditions. It also minimises the risk of damage due to physical stress, making them a reliable choice for demanding environments.

Ruggedness for Challenging Environments

The vibration-resistant design of DCS’s 200ah Lithium Batteries highlights their suitability for use in challenging environments. Whether in a moving vehicle, on vibrating machinery, or in remote, unstable locations, these batteries maintain their structural integrity and performance. This ruggedness provides users with the confidence that their power source will remain reliable and efficient, even under harsh physical conditions.

200 Amp Hour Battery – Our Batteries have Passed MIL-STD 810G Method 514.6

200 Amp Hour Battery – Our Batteries have Passed MIL-STD 810G Method 514.6

DCS takes pride in our lithium 200 Amp Hour Battery packs as these batteries have successfully passed the rigorous testing of MIL-STD 810G Method 514.6. This achievement underscores the batteries’ ability to withstand the specific challenges of vibration as outlined in military-grade testing standards. The MIL-STD 810G Method 514.6 test ensures that the batteries can endure various types of vibrations that they might encounter during their operational lifespan. Passing this test indicates a high level of durability and reliability, making these batteries suitable for both military and civilian applications where resilience is key.

Military-Grade Durability for Reliable Power

The accomplishment of passing MIL-STD 810G Method 514.6 with the 200 Amp Hour Batteries places DCS at the forefront of battery technology. This military-grade durability guarantees that the batteries are not only reliable but also capable of performing under extreme conditions. For users requiring a power source that can withstand rigorous and demanding environments, DCS’s 200 Amp Hour Batteries represent an optimal choice, combining resilience with exceptional performance.

Invest In A Fail-Safe 200 Amp Battery Design – If Any Component Fails, It Won’t Compromise The Battery Pack

Invest In A Fail-Safe 200 Amp Battery Design – If Any Component Fails, It Won’t Compromise The Battery Pack

Deep Cycle Systems (DCS) offers an innovative 200 Amp battery designed with a fail-safe mechanism. This design ensures that if any individual component fails, it does not compromise the integrity or functionality of the entire battery pack. This feature is particularly important in preventing power drainage from the battery cells and maintaining the battery’s overall efficiency and lifespan. Such a design is a hallmark of DCS’s commitment to reliability and user safety, making their batteries a smart investment for those who prioritise uninterrupted power and long-term value.

Ensuring Uninterrupted Performance and Safety

The fail-safe design of the 200 Amp battery by DCS is crucial for applications where consistent power is essential. In the event of a component failure, the battery’s ability to isolate the issue and prevent it from affecting the entire system ensures that the power supply remains stable and reliable. This not only enhances safety but also preserves the battery’s overall health and performance.

DCS 200ah Battery Deep Cycle – Ultra Safe and Explosion Proof Battery Pack

DCS’s 200ah Battery Deep Cycle is engineered for utmost safety, featuring an ultra-safe and explosion-proof battery pack. This design is a result of meticulous engineering and the use of advanced materials that prevent any risk of explosion, even in the most demanding environments. Safety is a paramount concern for DCS, and their 200ah battery is a testament to their dedication to producing secure, high-quality power solutions. This battery is ideal for users who need a dependable power source in environments where safety cannot be compromised.

Prioritising User Safety in Power Solutions

Prioritising User Safety in Power Solutions

The explosion-proof design of the DCS 200ah Deep Cycle Battery is a critical feature for ensuring user safety. By incorporating robust safety measures and using explosion-resistant materials, DCS provides peace of mind to users, knowing that their power source is not just efficient but also exceptionally safe. This battery is particularly suitable for applications where operational safety is a primary concern.

DCS 200ah Deep Cycle Lithium Battery is Known for Low Internal Resistance

The 200ah Deep Cycle Lithium Battery from Deep Cycle Systems is renowned for its low internal resistance. This characteristic is pivotal in enhancing the battery’s efficiency and performance. Low internal resistance means the battery can deliver more power and has a faster response time, making it an ideal choice for high-demand applications. Additionally, this feature contributes to less energy loss as heat, thereby improving the battery’s overall efficiency and lifespan. DCS’s focus on low internal resistance in their 200ah batteries reflects their commitment to providing high-performance power solutions.

Maximising Efficiency and Power Output

Low internal resistance in DCS’s 200ah Deep Cycle Lithium Battery translates to improved efficiency and power output. Users benefit from a battery that not only delivers power more effectively but also charges and discharges with greater efficiency. This makes the battery suitable for a wide range of applications, from renewable energy storage to high-powered electronics, where efficient energy transfer is essential.

200 Amp HR Battery – A Grade Cells for Battery Manufacturing

Deep Cycle Systems (DCS) presents the 200 Amp HR Battery, crafted using A-grade cells, the pinnacle of battery cell quality. This choice in manufacturing material ensures top-tier performance, longevity, and reliability. A-grade cells are known for their consistent output, higher energy density, and reduced risk of defects. This results in a battery that not only meets but exceeds performance expectations. DCS’s commitment to using the best materials in its 200 Amp HR batteries positions it as a leader in durable and efficient power solutions.

Superior Quality for Enhanced Performance

The use of A-grade cells in the 200 Amp HR Battery reflects DCS’s dedication to quality and excellence. These premium cells ensure that the battery delivers a stable and reliable power source, which is vital for applications where performance and dependability are crucial. It’s an assurance of quality that sets DCS batteries apart in the market.

200ah Lithium Battery Slim and Lightweight than A Lead-Acid Battery

200ah Lithium Battery Slim and Lightweight than A Lead-Acid Battery

DCS’s 200ah Lithium Battery Slim energy pack stands out for its slim and lightweight design, a stark contrast to traditional lead-acid batteries. This modern construction makes it an ideal choice for applications where space and weight are critical factors. The lightweight nature of this battery significantly eases installation and handling, while its slim profile allows for more flexible placement options. This combination of slimness and lightness without compromising power capacity is a testament to the advanced technology employed by DCS.

Enhancing Portability and Installation Flexibility

The slim and lightweight design of the 200ah Lithium Battery by DCS not only makes it more portable but also broadens its range of applications. It’s especially beneficial for mobile setups, RVs, and marine applications, where space and weight constraints are prevalent. This design innovation underscores DCS’s commitment to providing versatile and user-friendly power solutions.

Battery Deep Cycle 200ah Also Work as a Starter Battery That Provides 1200 Lithium Cranking Amps

The Battery Deep Cycle 200ah from DCS is uniquely versatile, doubling as a starter battery with the capability to provide 1200 Lithium Cranking Amps. This dual functionality makes it a highly sought-after product, offering both deep cycle and high cranking power. It’s particularly beneficial for vehicles and systems that require robust start-up power alongside reliable deep cycle energy for sustained operations. The 1200 Lithium Cranking Amps ensure that the battery can handle the high initial power demands of starting engines with ease.

Dual-Purpose Design for Enhanced Utility

DCS’s 200ah Battery’s ability to function as both a deep cycle and starter battery showcases its exceptional utility. This dual-purpose design is particularly advantageous for users seeking a single battery solution that covers all their power needs. The high cranking amps provide the initial power surge required for starting engines, while its deep cycle capabilities support continuous, long-term energy needs. This multifunctional approach reflects DCS’s innovation in battery design.

Lifepo4 200ah Comes with Bluetooth and WiFi Connectivity

Lifepo4 200ah Comes with Bluetooth and WiFi Connectivity

Deep Cycle Systems (DCS) elevates the standard with their Lifepo4 200ah battery, featuring both Bluetooth and WiFi connectivity. This integration of wireless technologies allows for seamless monitoring and management of the battery’s performance directly from a smartphone or computer. Users can effortlessly check charge levels and control settings and receive updates on their battery’s health, enhancing convenience and efficiency. This connectivity feature positions the Lifepo4 200ah at the forefront of modern battery technology, offering a user-friendly experience and greater control over power management.

Lifepo4 200ah with Enhanced User Interaction and Control

With Bluetooth and WiFi connectivity in the Lifepo4 200ah battery, DCS provides users with an unprecedented level of interaction and control. This technological advancement enables real-time monitoring and adjustments, ensuring that the battery operates at its optimal capacity. It’s a step forward in making energy management more accessible and user-friendly.

Operating temp Range of Lifepo4 Battery 12v 200ah is -30 to +110 Degrees C

The Lifepo4 Battery 12v 200ah from DCS boasts an impressive operating temperature range, functioning efficiently between -30 to +110 degrees Celsius. This wide range ensures that the battery remains reliable and effective in extreme conditions, from freezing cold to scorching heat. Such versatility makes it ideal for various applications, including those in harsh and fluctuating environments. The ability to operate across such a broad temperature spectrum underscores the robustness and adaptability of the Lifepo4 200ah battery, making it a suitable choice for challenging outdoor or industrial settings.

Reliable Performance in Diverse Environments

The extensive operating temperature range of the Lifepo4 battery with 12v 200ah capacity ensures its reliability in diverse environmental conditions. Whether used in cold climates or hot, the battery maintains consistent performance, demonstrating DCS’s commitment to providing versatile and durable power solutions to its customers.

Lifepo4 12v 200ah has IEC 62133 & 62619 Certification

Lifepo4 12v 200ah has IEC 62133 & 62619 Certification

The Lifepo4 12v 200ah battery from DCS is certified with IEC 62133 & 62619 standards, a clear indication of its quality and safety. These international certifications confirm that the battery meets stringent safety and performance requirements. IEC 62133 focuses on the safety requirements for batteries containing alkaline or non-acid electrolytes, while IEC 62619 specifies requirements for lithium secondary cells and batteries used in industrial applications. These certifications reassure users of the battery’s compliance with global safety and performance standards, solidifying its position as a reliable and trustworthy power source.

Lifepo4 12v 200ah with Global Standards for Safety and Quality

Achieving IEC 62133 & 62619 certifications for the Lifepo4 12v 200ah battery signifies DCS’s dedication to upholding international safety and quality standards. This compliance not only enhances user trust but also ensures that the battery is fit for a wide range of applications, from personal to industrial use. It’s a testament to DCS’s commitment to delivering superior and safe battery technology.

12v 200ah Lithium Ion Battery – Connect up to 10 Batteries in Parallel

Deep Cycle Systems (DCS) offers the versatile 12v 200ah Lithium Ion Battery, designed to cater to extensive power needs. One of the standout features of this battery is its ability to connect up to 10 units in parallel. This scalability allows users to significantly increase their power capacity, making it ideal for larger systems requiring substantial energy reserves. Whether for home energy systems, commercial setups, or recreational use, this parallel connection capability enhances both flexibility and power availability. It’s a feature that highlights DCS’s commitment to providing adaptable and powerful energy solutions.

Expanding Power Capacity with Ease

The ability to connect multiple 12v 200ah Lithium Ion Batteries in parallel from DCS empowers users to tailor their power systems to their specific needs. This scalability is particularly beneficial for applications that have dynamic power requirements. The ease of connecting these batteries in parallel ensures that users can effortlessly expand their system’s power capacity to meet increasing demands.

200ah Battery Deep Cycle – IP53 Ingress Protection

The 200ah Battery Deep Cycle by DCS is engineered with an IP53 ingress protection rating, ensuring resilience against dust and water. This rating indicates that the battery is protected against limited dust ingress and spraying water. Such protection is crucial for batteries used in outdoor or challenging environments, as it safeguards the internal components from external elements. The IP53 rating enhances the battery’s durability and reliability, making it suitable for a wide range of applications, including outdoor, marine, and industrial uses.

Enhanced Durability in Diverse Environments

With an IP53 ingress protection rating, the 200ah Deep Cycle Battery from DCS is built to last in diverse environments. This level of protection ensures that the battery can withstand exposure to dust and water, which is common in outdoor and industrial settings. Users can have confidence in the battery’s ability to perform reliably, even in less-than-ideal conditions, underscoring DCS’s dedication to creating robust and dependable power solutions.

Lithium Battery 12v 200ah can Be Connected in Parallel to Make a Bigger Power Bank

Lithium Battery 12v 200ah can Be Connected in Parallel to Make a Bigger Power Bank

Deep Cycle Systems’ Lithium Battery 12v 200ah is designed to be connected in parallel, allowing users to create a larger power bank to meet their specific energy needs. This flexibility ensures that whether you’re powering a large RV, an off-grid home, or an extensive marine system, you can achieve the required power capacity by combining multiple 12v 200ah lithium batteries. The ability to scale up your power storage without sacrificing efficiency or reliability makes the DCS lithium ion battery 12v 200ah an ideal choice for those needing customisable and robust energy solutions.

Lithium Battery 12v 200ah – Scalable Power Solutions

Experience scalable power solutions with the DCS Lithium Battery 12v 200ah, designed for easy parallel connection to meet the expanding energy needs of various applications, ensuring you have the power you need when you need it.

Lithium Battery 12v 200ah Provide 1200 Lithium Cranking Amps for Engine Starting

Lithium Battery 12v 200ah Provide 1200 Lithium Cranking Amps for Engine Starting

The Lithium Battery 12v 200ah from Deep Cycle Systems delivers an impressive 1200 lithium cranking amps, providing the high power necessary for reliable engine starting. This capability makes it an excellent choice for vehicles, boats, and generators requiring a powerful and dependable start. The DCS 12v 200ah Lithium Battery combines high-cranking power with the longevity and efficiency lithium technology is known for, offering users a superior alternative to traditional starting batteries.

High Power for Reliable Starting

Leverage the high cranking power of the DCS Lithium Battery 12v 200ah for reliable engine starting, ensuring your vehicles and equipment are ready to go when you are.

UN 38.3 Certification Ensure Lithium 200ah Slim Line Lithium Battery Do Not Rupture, Leak or Disassemble

UN 38.3 Certification Ensure Lithium 200ah Slim Line Lithium Battery Do Not Rupture, Leak or Disassemble

Deep Cycle Systems ensures the safety and reliability of its Lithium 200ah Slim Line Lithium Battery with UN 38.3 certification. This certification confirms that the battery has undergone rigorous testing and meets strict safety standards to prevent rupture, leakage, or disassembly under normal and extreme conditions. By choosing the DCS slim line lithium ion battery, users are selecting a power source that not only delivers exceptional performance but also adheres to the highest safety protocols.

Slim Line Lithium Battery – Certified Safety and Reliability

The UN 38.3 certification of the DCS Lithium 200ah Slim Line Lithium Battery guarantees users a safe and reliable energy solution, meeting the highest standards for peace of mind.

Slim Line Lithium Battery is Free From Electrical, Mechanical, and Thermal Abuses

The Slim Line Lithium Battery from Deep Cycle Systems is designed to withstand electrical, mechanical, and thermal abuses, ensuring a durable and resilient power source for various applications. This protection is critical for maintaining performance and safety, particularly in demanding environments where the risk of damage is higher. With the DCS Slim Line Lithium Battery, users can trust in a product that is built to last and perform under pressure, free from the common pitfalls that can affect battery integrity and lifespan.

Protection Against All Forms of Abuse

Trust in the robust design of the DCS Slim Line Lithium Battery, engineered to be free from electrical, mechanical, and thermal abuses, ensuring durability and long-lasting performance.

12v 200ah Lithium Battery – Get 200Amps for 1 Hour

The 12v 200ah Lithium Battery from Deep Cycle Systems is capable of delivering a continuous 200 amps for one hour, providing substantial power for high-demand applications. This feature is particularly beneficial for powering large systems and equipment that require a consistent and robust energy supply. The DCS 12 volt 200 ah lithium battery is ideal for users seeking a reliable power source that can handle intensive loads without compromising on performance or efficiency.

Consistent Power When It Matters Most

With the DCS 12v 200ah Lithium Battery, get consistent 200 amps for one hour, ensuring your high-demand applications are powered effectively and reliably when it matters most.

12v 200ah Lithium Battery – Efficient Charge and Discharge

Deep Cycle Systems’ 12v 200ah Lithium Battery is engineered for efficient charge and discharge cycles, maximising energy usage and extending battery life. This efficiency not only reduces the time needed for recharging but also ensures that energy is delivered more consistently, improving the overall performance of your power systems. The DCS 12v 200ah Lithium Battery stands out for its ability to maintain high levels of efficiency throughout its lifespan, making it an excellent choice for those requiring dependable and long-lasting power solutions.

Maximized Energy Utilisation

Experience maximised energy utilisation with the DCS 12v 200ah Lithium Battery, designed for efficient charge and discharge, enhancing the performance and longevity of your power systems.

48v Lithium Ion Battery 200ah – Powering Homes and RVs

The 48v lithium ion battery 200ah is a game-changer for energy solutions, offering unmatched versatility and efficiency for powering homes, RVs, and off-grid cabins. As a lightweight alternative to traditional batteries, this model from DCS ensures you have reliable energy wherever you need it. Its robust structure supports its effortless integration with solar systems, granting an environment-friendly power source that works flawlessly in fluctuating weather conditions.

DCS has yielded a high-performance, low-maintenance supply due to its extensive investment in research and development over the years. The sustained shift in energy technology marks a new era of investment aimed at obtaining energy independence. Without a memory effect, the 48V lithium-ion battery 200Ah ensures discharge rates for lower maintenance while guaranteeing outstanding capability throughout its lifespan.

Efficient and Durable 48v Lithium Ion Battery 200ah Solution

DCS focuses on incredible design whilst maximising transport-ability, which leads to the 48V Lithium Ion battery 200Ah. Regarding energy storage, look no further because this will cater to your every need. One of the key features of this stunning solution is it ensures minimal bulkiness and maximises energy density. The top reasons to choose the 48V lithium-ion battery 200Ah include:

- Simple to carry and put in place with minimal weight.

- Incredible cycle life of up to 500 charge and discharge cycles.

- Reduced stress and saved time due to elimination of maintenance.

- Compatibility with solar panels makes this a sustainable energy investment.

By choosing DCS, you are assured of an investment in a reliably efficient power source to meet all your energy needs.

Discover the Power of a 200Ah Battery for Home and Off-Grid Systems

A 200Ah battery offers more than just storage—it delivers the peace of mind that comes with reliable, long-lasting power. Whether setting up a solar system at home, heading off-grid, or prepping for backup during outages, this battery is a solid backbone for your setup. At Deep Cycle Systems (DCS), we’ve tailored our 200Ah batteries to suit Australia’s demanding conditions, both on and off the grid.

These batteries are built to last. With deep discharge capabilities, fast recharge times, and a rugged design, they’re perfect for homes, shacks, caravans, or anywhere you want solid, uninterrupted energy. They can power essentials like lights, fridges, routers—even tools if you’re running a shed or mobile setup. You’ll also appreciate the low-maintenance nature of a lithium 200Ah battery. Just install it, and it quietly gets on with the job, day after day, season after season.

How a 200Ah Battery Enhances Your Energy Storage Setup

How does a 200Ah battery fit into your system? Here’s where it shines:

- Handles heavy use, ideal for powering through long nights or cloudy spells

- Works smoothly with solar inverters and charge controllers

- Easily supports high-draw appliances without flicker or dip

- Fits neatly into compact storage cabinets or vehicle compartments

- Offers long cycle life with minimal maintenance

If you’re building an energy setup that you can count on, a 200Ah battery from DCS is a firm place to start. It works quietly in the background, but you’ll know it’s there when it matters.

Long-Lasting 200 Amp Hour Battery Ideal for High-Demand Usage

Power-hungry systems call for serious storage. A 200 amp hour battery gives you exactly that—solid, consistent energy delivery that won’t quit. Whether you’re powering a remote cabin, off-grid tools, or emergency equipment, this battery delivers much more than just volts and amps. It gives peace of mind.

DCS builds every 200 amp hour battery to handle harsh conditions. High demand? No problem. Frequent cycles? Bring it on. You’ll get smooth output, long life, and a battery that doesn’t need babysitting. It just works. It’s also a great fit for solar and hybrid systems. Its ability to manage charge and discharge efficiently stores more of your generated power and ensures it’s there when you need it.

Why the 200 Amp Hour Battery is a Trusted Choice for Power Backup

Not sure if it’s right for you? Here’s why people trust it:

- Keeps your setup running even when the sun isn’t shining

- Doesn’t lose charge quickly, so it’s ready for emergencies

- Pairs well with popular charge controllers and solar tech

- Handles heat and fluctuating loads like a champ

- Designed for daily use—no need to treat it gently

For people who rely on their power system every day, the 200 amp hour battery is a solid performer. DCS ensures it can keep up no matter what you throw.

Dependable 200 Amp HR Battery Built for Continuous Supply

There’s a reason so many folks are switching to a 200 amp HR battery. It’s not just about capacity—it’s about consistency. Whether you’re off-grid full-time or just need reliable backup, this battery delivers steady power across all your essential devices.

Deep Cycle Systems has crafted this unit to handle daily cycles, oversized loads, and the kind of wear that would knock out a lead-acid bank in half the time. And it’s not fussy. Plug it in, set it up, and let it do its thing. You’ll get high discharge efficiency, low internal resistance, and reliability, enabling you to forget it’s even there—until you need it.

Maximise Output with a 200 Amp HR Battery in Your Solar System

Here are a few reasons it’s a smart fit:

- Keeps your fridge, lights, and gear going even during grey days

- Plays well with hybrid and solar-only systems

- Doesn’t flinch at sudden surges or start-up loads

- Stays calm and stable under pressure

- Long lifespan equals long-term savings

Add it to your setup and see the difference. It doesn’t just store power—it keeps everything running smoothly.

Get Robust Energy Delivery with a 200 Amp Battery from DCS

Need muscle in your battery bank? The 200 amp battery has got you covered. It’s built for serious energy needs—whether you’re powering tools in the bush, running a mobile workshop, or want reliable backup for your home. This thing doesn’t flinch.

At DCS, we engineer our 200-amp batteries to deliver solid current day in and day out. With advanced lithium chemistry and a smart internal management system, they handle real-world demands without skipping a beat. Heat, vibration, or long draw times? It’s ready. Perfect for commercial setups, remote jobs, or adventurous setups where failure isn’t an option.

Applications That Benefit from a 200 Amp Battery

Here’s where it earns its keep:

- Powers up small business tools and emergency lighting without drama

- Handles rough rides in caravans or marine setups

- Keep your gear on when the mains drop out

- Stores solar energy efficiently for night-time use

- Compact enough to tuck into most battery bays

A 200 amp battery from Deep Cycle Systems is more than a backup—it’s a workhorse. And when everything’s riding on your energy supply, that’s precisely what you want.

Versatile 200Ah Deep Cycle Solutions for Solar and Marine Use

The 200Ah deep cycle battery is the quiet champion behind solar homes, marine setups, and off-grid cabins across Australia. It’s big on capacity, built for regular deep discharges, and made to go the distance. We’ve developed our 200Ah deep cycle options at Deep Cycle Systems for durability, safety, and all-day performance.

Whether you’re powering a boat, a shed in the bush, or your family home, this battery holds enough energy to support your lifestyle without constant recharging. There are no loud generators, no flickering power—just smooth, reliable energy that does its job.

When to Use a 200Ah Deep Cycle for Consistent Energy

Thinking about where this battery fits in? Here’s the lowdown:

- Powers fridges, lighting, and appliances on boats or in cabins

- Built to cycle daily without losing efficiency

- Great for weekenders, tiny homes, and off-grid solar systems

- Withstands the salt, heat, and movement of marine environments

- It plays well with solar charge systems, inverters, and alternators

If you’re after something that quietly powers your setup without fuss, the 200Ah deep cycle battery is a top pick. It’s made for people who live off the grid—or want to be ready when the grid drops.

High-Efficiency 200Ah Deep Cycle Battery for Long-Term Storage

When you invest in a solar setup, you want storage you can count on. The 200Ah deep cycle battery delivers reliable energy day and night, storing the sun’s output when you need it most. At Deep Cycle Systems, our lithium-based deep cycle batteries are designed for long life, steady voltage, and low maintenance.

Whether you’re backing up your household during outages or powering essential appliances off-grid, this battery is ready. It’s sized for serious usage but compact enough to install in tight spaces—ideal for homes, sheds, or even mobile rigs.

What Makes the 200Ah Deep Cycle Battery a Smart Investment

Not all batteries are created equal. Here’s what sets this one apart:

- Stores energy efficiently, especially from solar panels

- Delivers consistent power across every discharge cycle

- Can be mounted in multiple positions for space-saving installs

- Resists damage from deep discharging and rough handling

- Lasts for thousands of cycles without fading

A 200Ah deep cycle battery is more than just backup—it’s a core part of a stable, efficient energy system. Built to work when you need it, without a second thought.

Compact 200Ah Battery Deep Cycle Built for Performance

Some setups demand high output without taking up too much room. That’s where the 200Ah battery deep cycle shines. It’s a compact, high-capacity battery built to power your life without needing an entire shed to house it. At Deep Cycle Systems, we design each unit to meet the needs of modern Aussie households, travellers, and trades.

Whether running a fridge in your caravan, lights in a shed, or a full off-grid home setup, this battery packs serious performance into a manageable size. It handles harsh environments, rapid discharges, and long loads—all with minimal maintenance.

Why Install a 200Ah Battery Deep Cycle in Remote Setups

Off-grid or off-the-beaten-track? This one’s for you:

- Provides long-lasting power without grid access

- Ideal for remote homes, workstations, and mobile units

- Recharges quickly with solar or generator input

- Slim profile fits snugly into trailers, campers, or sheds

- Requires zero upkeep—just set and forget

If you want quiet, dependable power where the grid won’t reach, the 200Ah battery deep cycle is your go-to. It’s the power you can count on wherever you are.

Battery Deep Cycle 200Ah Designed for Renewable Power Systems

Every renewable setup needs strong storage, and the battery deep cycle 200Ah delivers. Designed specifically for solar systems, wind setups, and hybrid installations, this battery stores more energy, lasts longer and cuts the cost of replacements. At DCS, we build battery deep cycle 200Ah units that perform day in and day out.

It’s ready to go wherever you need: your solar shed, van conversion, or bush retreat—no fumes, noise, or fuel—just reliable, renewable power.

Choosing the Right Battery Deep Cycle 200Ah for Your Needs

Here’s why this model is a favourite across Australia:

- Optimised for solar and renewable energy systems

- Offers a high usable capacity without drop-offs

- Performs in hot, dry, coastal, or remote conditions

- Easy to integrate with existing charge gear and inverters

- Long service life cuts down on replacement and labour costs

DCS battery deep cycle 200Ah options are more than batteries—they’re long-term solutions for independent energy. Set it up, plug in, and relax, knowing your power is sorted.

High-Capacity 200Ah Lithium Battery for Maximum Runtime

When uptime matters, a 200Ah lithium battery is the gear you want in your corner. Designed for maximum runtime and dependable discharge, this battery is ideal for off-grid homes, backup systems, caravans, and solar setups that need serious staying power. At Deep Cycle Systems, we build our batteries with Australian conditions in mind—so you get performance, even when the weather doesn’t cooperate.

With its lightweight lithium construction and high energy density, this battery stores more power in less space. You get a quick recharge, long service life, and reliable voltage throughout every cycle. It’s simple: fewer replacements, more time doing what matters. Whether powering daily loads or relying on it during outages, this battery does the job efficiently and quietly—no noise, no fumes—just clean, solid power.

What Sets a 200Ah Lithium Battery Apart from Traditional Options

Here’s what makes the upgrade worth it:

- The lightweight build makes it easy to install or relocate

- Delivers full power without fading, even under load

- Charges faster than AGM or lead-acid alternatives

- Safer lithium chemistry with thermal and overcharge protection

- Long cycle life means better value over time

A 200Ah lithium battery from DCS isn’t just a component—it’s the heart of a smarter, stronger energy system.

Reliable 200Ah Lithium Packs for Modern Power Demands

Modern energy systems, from smart homes to mobile workstations, need more than just power—they need reliability. The 200Ah lithium pack from Deep Cycle Systems answers the call with a blend of efficiency, safety, and ease of use. It’s perfect for people who depend on their setup, whether for work, travel, or peace of mind at home.

This lithium pack is designed to be scalable, lightweight, and durable. It handles deep discharges, frequent cycles, and fluctuating loads without skipping a beat. Whether you’re in the middle of the Outback or a suburban shed, it just works.

Integrating a 200Ah Lithium into Your Power Strategy

Need something that fits right in? Here’s why it does:

- Easily connects to existing solar and backup setups

- Delivers clean, stable voltage even under stress

- Can be expanded with parallel battery banks

- Compatible with smart energy monitoring systems

- Requires no regular maintenance or top-ups

If you want reliability in your energy plan, this 200Ah lithium battery should be part of it.

Advanced Lithium 200Ah Battery Engineered for Efficiency

Efficiency isn’t just about saving power—it’s about using it smartly. The lithium 200Ah battery from DCS is built to deliver that edge. Every bit of energy you store gets used more effectively, and every charge lasts longer. It’s the kind of battery that quietly makes your whole system better.

We’ve engineered it for the real world: hot days, high loads, and extended runtime. It handles surges and recharges fast. And with built-in safety features, it protects your system and peace of mind.

The Key Features of a Lithium 200Ah Battery for Daily Use

Why it outperforms the rest:

- Delivers stable output all day long

- Withstands tough environments—heat, dust, vibration

- The recharge rate lets you top up between short sun windows

- Long cycle life = better ROI over time

- The sealed design makes it ideal for indoor or tight installs

In short? The lithium 200Ah battery is built to work hard without needing constant attention.

The Best 200Ah Lithium Battery for Off-Grid and Backup Power

Searching for the best 200Ah lithium battery? This one ticks all the boxes. It offers high performance, long life, minimal maintenance, and reliable delivery—all packed into one powerful unit. DCS has spent years perfecting its lithium technology so you get everything you need without the drawbacks of older battery types.

It’s the ideal battery for remote homes, caravans, backup power stations, and hybrid systems. Whether you’re going fully off-grid or just want to protect against blackouts, it provides dependable energy every time.

Why the Best 200Ah Lithium Battery Offers Long-Term Savings

More than just power—it’s about value:

- Holds charge longer and discharges deeper than legacy batteries

- Outlasts lead-acid models by several thousand cycles

- Needs no water top-ups or acid checks—ever

- Packs serious power into a compact, lightweight frame

- Backed by reliable DCS service and local expertise

You’re not just buying a battery but investing in energy independence. And with the best 200Ah lithium battery, that investment goes a long way.

Durable Lithium Ion Battery 200Ah for Residential & Mobile Use

When you’re setting up an energy system for your home or vehicle, choosing a lithium ion battery 200Ah makes a world of difference. These batteries are built to handle everything from day-to-day energy needs to emergency backups, all while staying compact and easy to manage. At Deep Cycle Systems, we design batteries that stand up to the harsh Australian climate—no matter where you take them.

Whether you’re powering a residential solar system or a 4WD camper setup, this 200Ah lithium ion battery offers exceptional runtime and quick recharge. It’s made with high-grade cells that deliver clean, consistent voltage, and the sealed casing means it’s safe for use indoors or on the move. Unlike old-school batteries that need constant attention, this one’s built to be low-maintenance and long-lasting. It’s ideal for anyone looking for energy independence—off-grid homeowners, vanlifers, or those who just want to stop worrying about blackouts. Install it once, and you’re set for years.

Benefits of Using a Lithium Ion Battery 200Ah over Lead-Acid

Wondering if the switch is worth it? Here’s what you get:

- Faster charging, even with limited solar input

- Lighter weight makes installation easier and safer

- Delivers more usable power per cycle

- No off-gassing, acid leaks or regular maintenance

- Longer service life, saving you money long-term

Switching to a lithium ion battery 200Ah is about simplifying your setup and improving reliability. With DCS, you’re not just buying a battery—you’re choosing smarter energy for wherever life takes you.

Industrial-Grade 200 Amp Lithium Ion Battery for Heavy Loads

When the job demands serious power, a 200 amp lithium ion battery delivers. This high-output solution is perfect for machinery, tools, backup systems, and industrial equipment where voltage dips just aren’t an option. Built by Deep Cycle Systems, this battery is engineered to keep your systems running strong—even under the toughest load conditions.

With its high discharge rate and long lifecycle, it’s ideal for both mobile workstations and fixed setups. Whether you’re operating remote field equipment or powering a tradesman’s rig, the battery’s durable casing and internal BMS (Battery Management System) ensure stable output and protection against overcharge, overheating, or over-discharge. You get peace of mind knowing your equipment is powered by something designed to work, not fail, when it counts most.

How a 200 Amp Lithium Ion Battery Handles Peak Demand

Here’s why it handles pressure so well:

- Delivers consistent high current without voltage drop

- Designed for tools and machines with start-up surge needs

- Built-in protection against thermal or electrical overload

- High recharge efficiency reduces downtime

- Vibration-resistant and safe for vehicle or trailer mounting

If your system can’t afford a hiccup, this 200 amp lithium ion battery is the upgrade it needs. Trust DCS to keep your gear running when it matters most.

Efficient Li Ion Battery 200Ah with Fast Recharge Capabilities

Energy efficiency isn’t just a buzzword—it’s essential. The li ion battery 200Ah is perfect for those looking to maximise solar usage, reduce generator time, and enjoy more freedom in off-grid living. With fast charging and high output, this battery is built for people who want dependable energy without fuss.

At Deep Cycle Systems, we design our batteries with real-world users in mind. Whether you’re in a tiny house, RV, or remote work site, our 200Ah battery is slim, smart, and ready to go. It easily replaces bulky lead-acid units and integrates smoothly with solar panels, inverters, and other system components. If you’ve dealt with sluggish charging and poor performance from older batteries, this will feel like a serious upgrade.

What You Gain by Upgrading to a Li Ion Battery 200Ah

It’s not just about power—it’s about control:

- Recharges up to 5x faster than AGM or flooded batteries

- Lightweight design cuts down on structural stress

- Maintains voltage under load, great for sensitive devices

- No memory effect or sulphation issues

- Works in extreme heat without losing efficiency

With a li ion battery 200Ah, you’re investing in energy freedom. No more worrying about cloudy days, shallow discharges, or clunky old tech. Just plug in and power on.

12V 200Ah Lithium Ion Battery for Off-Grid Solar and Storage

Planning to live off-grid or just want more independence from the grid? The 12V 200Ah lithium ion battery is your go-to solution. It offers dependable power storage for solar setups, emergency systems, and mobile lifestyles, all with the peace of mind that comes from advanced lithium technology.

This battery stores a serious amount of energy without taking up half your shed or vehicle. Built for deep cycling, it can handle the daily charge/discharge routine without breaking a sweat. And with smart protection features, you’re safe from overheating, overcharging, or deep discharge failures—no need to babysit your power source. From back sheds to bushland setups, it’s the battery Aussies are turning to for self-sufficiency.

Why the 12V 200Ah Lithium Ion Battery is a Reliable Backup

It’s more than just backup—it’s peace of mind:

- Charges efficiently even with partial solar days

- Holds voltage over long periods of inactivity

- Easily integrates with inverters and charge controllers

- Quiet, clean, and emission-free operation

- Outlasts lead-acid alternatives by thousands of cycles

When the grid goes down, the 12V 200Ah lithium ion battery from DCS keeps your lights on, your fridge running, and your family secure.

Reliable 12V 200Ah Lithium Battery for Every Environment

A 12V 200Ah lithium battery isn’t just about capacity—it’s about confidence. Whether you’re powering an off-grid home, a caravan, or a remote worksite, this battery delivers consistent, reliable energy no matter the weather or workload. At Deep Cycle Systems, we’ve designed this unit for harsh Australian conditions, making it perfect for both extreme heat and unpredictable environments.

Thanks to its lithium iron phosphate (LiFePO4) chemistry, you’ll get a safer, longer-lasting battery with minimal degradation over time. It’s compact and efficient, making it ideal for tight spaces or mobile installations. With a fast recharge rate and low self-discharge, this battery is always ready when you are—no trickle charging or complicated maintenance required.

The 12V 200Ah lithium battery is also a favourite among DIY solar system builders and commercial operators alike. It integrates easily with standard inverters and solar charge controllers, and the internal BMS protects against common issues like overvoltage or overheating.

How to Pair a 12V 200Ah Lithium Battery with Your System

Make it work smarter, not harder:

- Use in parallel for increased capacity or voltage scaling

- Compatible with 12V and 24V inverters and chargers

- Ideal with MPPT solar charge controllers for faster charging

- Add monitoring via Bluetooth for performance tracking

- Works seamlessly with solar, wind, or hybrid power inputs

Pairing a 12V 200Ah lithium battery with your setup means fewer headaches, more uptime, and the kind of energy resilience that puts you in control—wherever you are.

Optimised Lithium Battery 12V 200Ah for Day-Night Use

The lithium battery 12V 200Ah is purpose-built for setups that don’t stop when the sun goes down. Whether you’re running appliances overnight in an off-grid home or keeping lights and communications going at a remote jobsite, this battery is a reliable energy storage solution that handles the full cycle—day and night. At Deep Cycle Systems, we understand how unpredictable the Australian environment can be.

That’s why our 12V 200Ah lithium batteries are engineered to charge quickly when solar is available, and hold enough power to carry through extended cloudy days or overnight loads. With high discharge efficiency and deep cycle capabilities, this battery gives you more usable energy when it really counts. It’s also a solid investment in long-term savings. With a lifespan of up to 10 years, it far outpaces traditional lead-acid options and cuts down on replacement and maintenance costs.

Why Households Choose a Lithium Battery 12V 200Ah

What sets it apart in everyday use?

- Keeps powering essentials through nighttime hours

- Minimal voltage drop under load—great for sensitive gear

- Operates quietly with no emissions or fumes

- Fits easily into standard battery housings

- Built-in BMS protects your investment from day one

Choosing a lithium battery 12V 200Ah isn’t just about capacity—it’s about peace of mind. It works when you need it, how you need it, and lasts longer than the rest.

Rugged 200 Amp Lithium Battery Built for Industrial Needs

For high-demand environments, the 200 amp lithium battery from Deep Cycle Systems delivers rugged, high-output performance that professionals can count on. This isn’t just another battery—it’s built to power serious equipment under serious conditions. Whether it’s remote job sites, large off-grid systems, or backup for high-load electrical appliances, this battery doesn’t flinch.

It provides fast response time, steady output, and impressive thermal stability, all within a compact and transport-friendly case. Its lithium chemistry enables higher efficiency and deeper discharge cycles, ensuring your equipment stays powered longer without compromising battery health. Designed for everything from off-grid cabins to field service trailers, it can be mounted securely in any orientation and integrated with smart monitoring tech to track every watt.

Where a 200 Amp Lithium Battery Delivers the Best Results

Put it where performance matters most:

- Remote worksites running high-draw tools

- Emergency power setups in health or comms infrastructure

- Hybrid renewable energy systems with fluctuating loads

- Commercial transport fleets needing stable voltage

- Utility trailers or portable workstations in rugged terrain

The 200 amp lithium battery gives you one less thing to worry about—solid, steady, no-nonsense power for when the job can’t wait.

Long-Cycle 200 Amp Hour Lithium Battery for Smart Energy Management

In a world of rising energy demands and shifting grid reliability, the 200 amp hour lithium battery stands out as a dependable, long-cycle solution for smart energy storage. With advanced lithium technology, this battery can handle deep discharges, fast charging, and thousands of cycles—all with minimal degradation over time.

Built to integrate with solar, wind, or backup generator systems, it’s a perfect fit for households and businesses alike. Deep Cycle Systems has tailored this unit for both performance and safety, using durable materials and internal BMS to regulate performance and extend lifespan. Whether you’re using it to run a backup system, support evening loads, or smooth out intermittent solar supply, this battery works silently and efficiently in the background—giving you full control over your power usage.

The Advantages of a 200 Amp Hour Lithium Battery in Backup Systems

Why choose this for backup power?

- Quick recharge ensures you’re ready after an outage

- Maintains voltage stability during extended use

- Compact design fits in tight mechanical rooms or panels

- No fumes, no acid—safe for indoor installation

- Built to deliver up to 5,000+ charge cycles

With a 200 amp hour lithium battery in place, your backup power isn’t just ready—it’s reliable, efficient, and built to last.

Slimline Lithium Battery Built to Fit Tight Installations

If you’re working with limited space—think camper vans, utility compartments, or custom setups—a slimline lithium battery could be the perfect fit. At Deep Cycle Systems, we’ve engineered this battery for tight installations without sacrificing capacity or performance. You get a powerful lithium solution that’s easy to mount, easy to access, and incredibly reliable.

This battery is ideal for users who don’t have room for bulky boxes but still need solid, high-capacity energy storage. It’s designed to slide into cabinets, trays, or narrow compartments without needing extra space for ventilation or maintenance. Built-in BMS (Battery Management System) keeps everything running safely, while its sealed, rugged casing means it can handle bumps, dust, and even some rough Aussie road conditions. For mobile and off-grid setups where space-saving is non-negotiable, this slimline lithium battery delivers where others simply can’t.

Why a Slimline Lithium Battery is Perfect for Compact Spaces

Here’s where it shines:

- Slim profile mounts vertically or horizontally

- Safe for enclosed areas thanks to no gas emissions

- Lightweight for easy transport or mobile use

- Perfect for RVs, boats, utes, and caravans

- Integrates with solar, AC, and DC systems seamlessly

When space is limited, but your power needs aren’t, a slimline lithium battery from DCS is a reliable, compact solution that lets you build smarter.

Powerful Yet Slim: 200Ah Slimline Lithium Battery by DCS

Need long-lasting power in a compact format? The 200Ah slimline lithium battery is specifically designed for those who need serious energy storage but don’t have room to spare. At Deep Cycle Systems, we’ve packed all the power and reliability of our standard lithium range into a slimline profile that’s easier to install in tight areas.

Whether you’re building an overlanding rig, modifying a caravan, or powering a mobile workstation, this battery gives you the storage capacity to run fridges, inverters, pumps, lights, and more—without taking up precious space. Plus, with advanced lithium iron phosphate cells, you get high energy density, better thermal management, and a longer lifespan than traditional battery types. The DCS 200Ah slimline lithium battery also offers incredibly low internal resistance, meaning less energy loss and quicker recharge when connected to solar or DC sources.

How the 200Ah Slimline Lithium Battery Maximises Usable Space

The design pays off here:

- Mounts flat under beds, seats, or compartments

- No need for air gaps or acid-proof trays

- Stackable or pairable for increased storage

- Minimal weight strain on vehicle frames

- Includes fast-connect terminals for clean wiring

For anyone needing performance without bulk, the 200Ah slimline lithium battery by DCS is an innovative, space-saving choice that doesn’t compromise capability.

Space-Saving Slimline Lithium Battery 200Ah for Utes & Vans

Installing a full-sized energy system in a van or Ute can be challenging, but that’s where the slimline lithium battery 200Ah comes into play. It’s slim, rugged, and engineered to slide right into trays, canopies, or custom compartments without wasting an inch of space. With its high capacity and low profile, it’s built for people who need efficient energy on the move.

The slimline form factor makes it ideal for tradies, campers, and van lifers who need reliable power for fridges, lighting, inverters, or even 240V appliances. And unlike lead-acid systems, you fully use your 200Ah capacity—no shallow cycling or voltage sag under load. Backed by Deep Cycle Systems’ commitment to quality, this battery offers more than a slim shape—it’s a complete solution designed to handle Australia’s rugged conditions efficiently.

Key Features of a Slimline Lithium Battery 200Ah

Why it’s so popular among mobile setups:

- Fits snugly behind drawers or beneath false floors

- Designed for mobile use—no leaks, no maintenance

- Handles vibrations and heat without degradation

- Compatible with solar, alternator, and shore charging

- Protects devices with clean, consistent output

For mobile professionals or weekend explorers, the slimline lithium battery 200Ah upgrade makes your build cleaner, lighter, and more capable.

Reliable 200Ah Lithium Battery Slimline for Mobile Setups

When your power system needs to move with you, the 200Ah lithium battery slimline design becomes a game changer. Unlike bulky batteries that require major space or complex mounting, this model is ready to go right into your tray, van, or caravan build—no special brackets or large compartments are needed.

Despite its compact shape, this battery packs the full punch of a 200Ah lithium bank. That means reliable overnight use, the ability to run energy-hungry gear like induction cooktops or portable aircon, and extended off-grid stays without worrying about capacity. It’s a favourite among Australian travellers who demand performance without hassle. With DCS quality built-in, you also get a rugged casing, internal cell balancing, and thermal safeguards to keep you going safely and efficiently.

Using a 200Ah Lithium Battery Slimline in Travel and Work Vehicles

Why it’s ideal on the move:

- No acid or off-gassing—safe for cabins or enclosed trays

- The ultra-thin profile fits under platforms or in side cavities

- Easily links with inverters, chargers, and solar

- Resists shock and movement on uneven roads

- Quick to install and simple to monitor

The 200Ah lithium battery slimline provides professional-grade energy in a practical, portable format. It is perfect for those who live or work on the road and don’t have time for bulky systems or fragile tech.

Compact 200Ah Lithium Battery Slim Form for Modern Builds

If you’re designing a system where space matters as much as performance, the 200Ah lithium battery slim is your perfect solution. At Deep Cycle Systems, we’ve engineered this battery for tight spaces without compromising power. Whether you’re working on a mobile setup, tiny home, or commercial installation, this compact unit delivers the full 200Ah capacity in a footprint that fits just about anywhere.

Its slim form means it can slide under vehicle seats, behind drawers, or into wall cavities, making it ideal for custom builds. But don’t let its size fool you—this battery is all lithium iron phosphate, offering excellent discharge depth, high energy density, and built-in safety management. Whether you’re powering off-grid appliances, lighting systems, or sensitive electronics, the 200Ah lithium battery slim delivers quiet, consistent power all day and night.

Why the 200Ah Lithium Battery Slim is a Top Pick for Custom Systems

Here’s why pros and DIYers love it:

- Ultra-slim profile fits builds others can’t

- Full 200Ah capacity, not just “rated” but truly usable

- Lightweight design reduces frame strain and improves installation ease

- Internal BMS keeps the battery protected at all times

- Pairs easily with solar, DC-DC chargers, and inverters

When you need performance in a tight package, the 200Ah lithium battery slim offers flexibility, safety, and serious power—without compromise.

Safe and Efficient LiFePO4 200Ah Battery for Everyday Use

If safety, longevity, and performance are your priorities, a LiFePO4 200Ah battery is the gold standard. Short for lithium iron phosphate, LiFePO4 batteries offer the best balance between power output and long-term reliability. Whether for home energy storage, a mobile workstation, or an off-grid getaway, this battery is built to handle everything safely and efficiently.

At Deep Cycle Systems, our LiFePO4 200Ah battery is designed for residential and commercial users who demand steady voltage, long cycle life, and robust internal protection. It features high thermal stability, a built-in Battery Management System, and zero maintenance, making it ideal for applications where safety is critical. Unlike older chemistries, this battery is inherently stable, with no risk of thermal runaway or sudden discharge failures. It also holds its charge longer and delivers more usable power per cycle.

Advantages of Using a LiFePO4 200Ah in Harsh Conditions

Why it’s a standout performer:

- Operates safely in high-heat and rugged conditions

- Long cycle life: up to 5,000+ full discharges

- No maintenance, no fumes, no acid corrosion

- Delivers consistent voltage from full charge to empty

- Lightweight and easy to transport or install

Whether working in the outback or powering a home system, the LiFePO4 200Ah battery offers peace of mind with dependable performance in the most demanding environments.

Premium LiFePO4 Battery 12V 200Ah for Off-Grid Living

Living off the grid doesn’t mean sacrificing comfort or consistency—primarily when your system is powered by a LiFePO4 battery 12V 200Ah. This battery offers high-capacity energy storage in a compact, reliable package, giving you the freedom to power everything from lights and fridges to communication gear and power tools—day and night.

Deep Cycle Systems designs our 12V 200Ah LiFePO4 batteries for real-life Australian conditions. That means rugged casing, thermal protection, and a sealed design that can handle heat, dust, and bumpy rides. The built-in BMS protects your battery from overcharging, deep discharges, or overloads. Its ability to provide deep cycling performance without degradation makes it an excellent choice for solar setups, especially in remote or mobile environments.

What Makes a LiFePO4 Battery 12V 200Ah Reliable for Long-Term Use

Built for resilience and return on investment:

- Stable output over thousands of cycles

- Fast charging with MPPT or DC-DC inputs

- Lightweight casing—easy to mount or relocate

- No memory effect or capacity fade

- Performs well in extreme Aussie heat or cold

With a LiFePO4 battery 12V 200Ah, you’re not just buying energy storage—you’re investing in the kind of reliability that lets you live freely, sustainably, and independently.

Advanced LiFePO4 12V 200Ah Battery Engineered for Longevity

If you’ve ever dealt with a battery that gave out too soon or couldn’t handle a bit of heat, you’ll know why the LiFePO4 12V 200Ah battery is in a league of its own. Designed to last the distance, it’s perfect for people who want a reliable energy source that keeps working—day in, day out.

This isn’t one of those “showroom only” batteries that look great on paper but struggle in real Aussie conditions. It handles high temps, uneven loads, and the long hours of use you get with solar setups, off-grid cabins, or even mobile trailers. And because it uses lithium iron phosphate chemistry, you don’t have to worry about fire risk or voltage drop after a few months of use.